S-BIRD: Japan’s first environmental testing center for aircraft equipment

February 15, 2021

February 15, 2021

S-BIRD

The Central Hub for Industrial Development and Human Resource Development

Previous Technical high school was renovated and now reborn as S-BIRD.

The Goals of S-BIRD

Create Leading Industries through Cooperation between Industry, Government, and Academia

S-BIRD is a facility that was created with the aim of advancing and realizing the added value of aircraft and other industries in Iida region through the cooperative efforts of organizations in Nagano Prefecture/Japan.

Based on the “Nagano Prefecture Aircraft Industry Promotion Vision” established in 2016, Nagano Prefecture has set out to create Japan’s first full-spectrum center oriented toward aircraft systems, incorporating human resource development, research and development, and verification testing. Minami Shinshu Wide Area Union is striving to create leading industries in this area to play a role in the overall international strategic zone known as the “Special Zone to Create Asia No.1 Aerospace Industrial Cluster”.

Nurture the Human Resources and Technologies to Drive the Future

S-BIRD has comprehensive test laboratories geared toward aeronautic technology and local industry. Furthermore, there is research and education performed through our standing as a campus with “Aircraft System Collaborative Research Courses” held by Shinshu University. Minami Shinshu Wide Area Union also serve as an administrative window for technological and managerial support for businesses and entrepreneurs, and has the ability to broadcast the allure of local products of Iida region.

(Reference source: http://www.isilip.com)

Iida Region

Tamagawa Seiki:

Aircraft Components Manufacturer

Tier 1 and 2

S-BIRD:

Human Resources Cultivation System

Industrial Cluster:

Cooperation among Regional Company

S-BIRD:

Aircraft System Testing Site & Public Facility

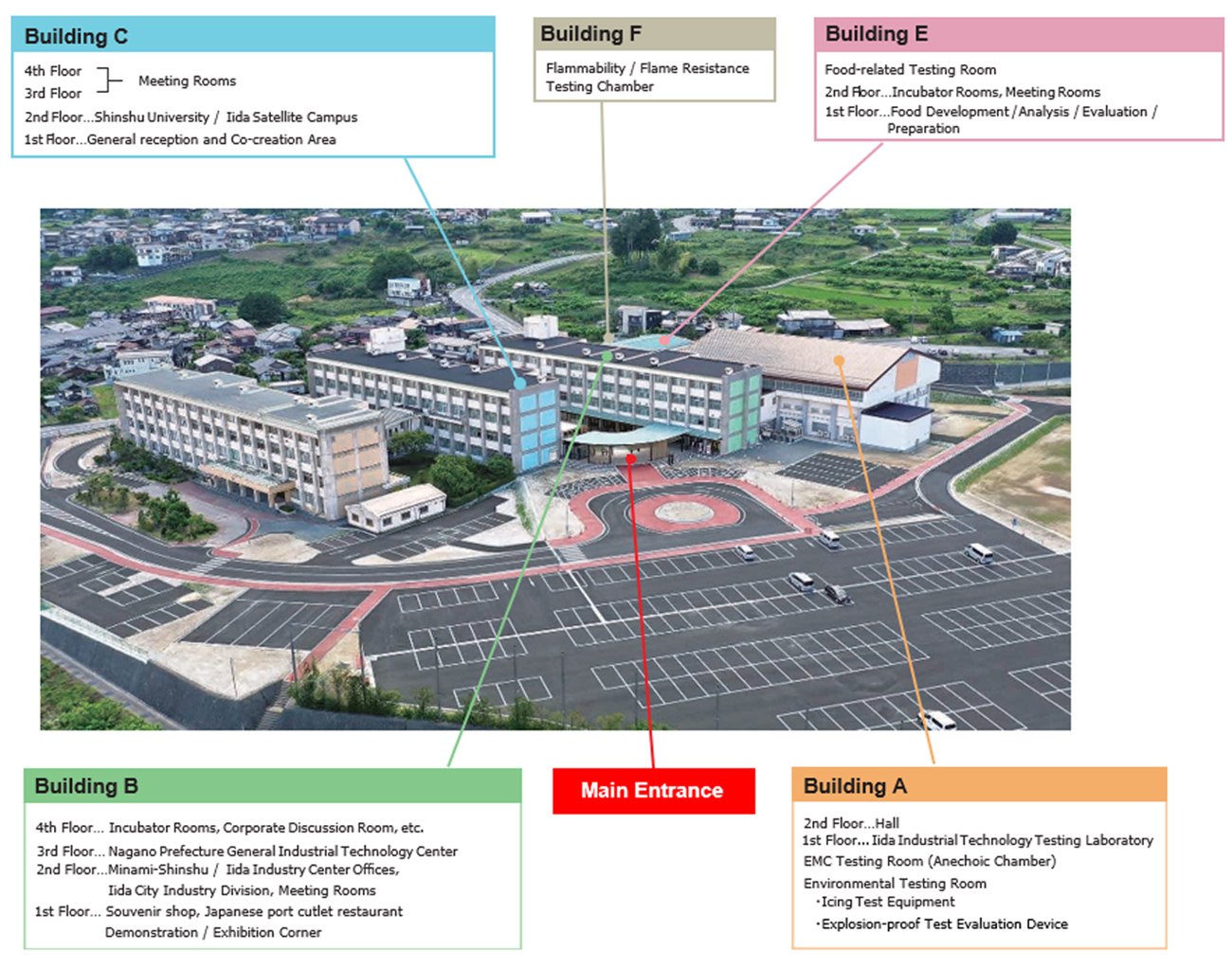

Floor Map

Main Entrance

An experimental aircraft actually used in high-speed flight demonstrations is displayed in the main entrance. This demonstration was performed by the former National Space Development Agency (NASDA*) and the former National Aerospace Laboratory (NAL*) (*: currently JAXA).

Tamagawa Seiki Co., Ltd. was involved in the development of a complex inertial device that controls this demonstration aircraft.

Access

(Reference source: http://www.isilip.com)

S-BIRD

Address: 3349-1, Zakoji Iida City, Nagano

TEL: +81-(0)265-52-1613

FAX: +81-(0)265-24-0962

Minami-Shinshu Iida Industry Center (within S-BIRD)

http://www.isilip.com/

Building A

Industrial Technology Test and Research Laboratory

The Industrial Technology Test and Research Laboratory in S-BIRD is Japan’s first environmental testing center for aircraft equipment. This facility offers a wide variety of services for companies that are involved in the development of new technologies and new products, including requested testing, calibration of measuring equipment. Tamagawa Seiki is a member of this working group joining nation, local governments and deeply committed to its activities.

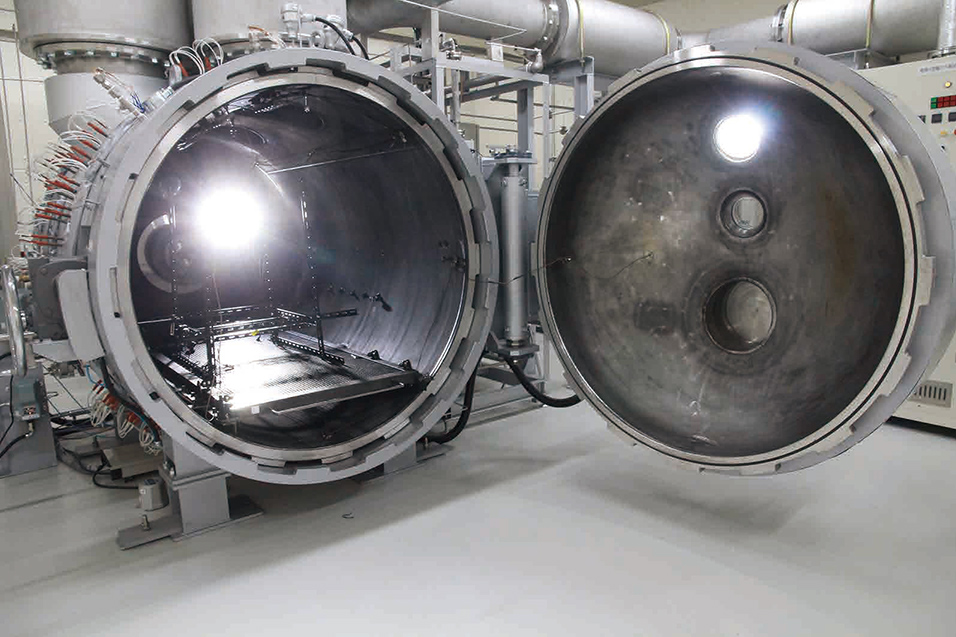

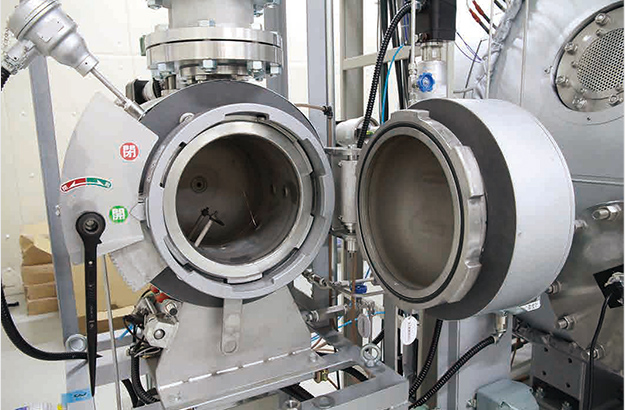

Explosion Proof Test Chamber

Flammability testing for fuel tank peripheral equipment

Flammability testing equipment was introduced in 2017. This equipment is used to see if a fuel tank peripheral equipment will not ignite and explode in case of its being exposed to fuel in in-flight aircraft. Sensors and actuators which are often installed around the tank will be the main target products for this testing.

Weight of the main chamber is about 10 tons.

Japan’s first test equipment

Explosion Proof Test Chamber complies with RTCA-DO160G Section 9. It is not only Japan’s first equipment to comply with this standard but also world’s first equipment to control all processes automatically.

This Explosion Proof Test Chamber also supports for US military standard for Environmental Engineering Considerations and Laboratory Tests, MIL-STD-810 testing. MIL standard is widely used as a standard for commercial-off-the-shelf products and it can be applied to various fields of testing not limited to aerospace products.

Test procedure

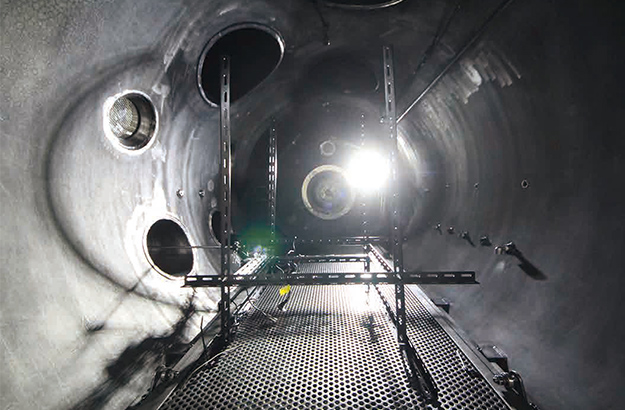

First, puts the test piece into a 1.5 m inner diameter and 2.0 m depth cylindrical chamber. Then sprays a simulated aviation fuel (normal hexane) changing the air pressure and temperature with the chamber sealed. Not only offers visual observations on the testing through tempered glass windows but also offers the records using high speed camera. Test piece can be controlled using a manipulator.

Opens the clutch door. It is like a huge pressure cooker.

Inside the chamber; Lightning, cameras, fuel spray nozzles, sensors, are installed.

The control panel enables both program operation according to specific standards and manual operation.

Reproduce altitudes up to 100,000 feet

This Explosion Proof Test Chamber supports the pressure range from 101.3 kPa to 4 kPa and this reproduces the altitude of 100,000 ft (30,480 m) which is equivalent to the level of satellites orbit. The temperature range is 10 to 260 degree C, and it also reproduces a rapid temperature change from room temperature to 150 degree C within 90 minutes. The Explosion Proof Test Chamber controls these conditions automatically.

Environmentally- & human body-friendly equipment

S-BIRD is located near a residential area. Taking a special care of its location, S-BIRD has a large silencer that reduces the explosion sound by less than 65 dB. And also has automatic processing equipment that decomposes unburned gas and render the gas harmless.

Developed and manufactured by local company

Design and manufacturing of Explosion Proof Test Chamber were outsourced to Hanyuda Co., Ltd. in Nagano City, and the development was supervised by FAA quality inspector. Hanyuda is a traditional pressure vessel manufacturer having its expertise skills in manufacturing of high pressure mushroom sterilizers. Tamagawa Seiki gave advice to Hanyuda on its specifications as a member of the working group.

An eye-catching huge silencer on the top of the chamber. The equipment on the left is a sub-chamber.

Check to see if the fuel used in a testing burns in the sub-chamber.

Don’t miss it!! Introduction in next Newsletter

Temperature/Altitude/Humidity Icing Test Chamber

Flammability and Fire-resistance Testing Equipment

OUR TECHNOLOGIES

CAN HELP YOUR EVELOPMENT

Application for Cockpit /

Pilot Control

Tamagawa supplies many variety of products for Cockpit/Pilot control systems of commercial aircraft. Small sized electrical motors, angular sensors (Resolvers & RVDTs), linear sensors (LVDT) and control levers are available for your Cockpit / Pilot Control systems.

Application for High Lift

System

Tamagawa has the capability to design the products for high lift system used for increasing lifting power during takeoff and landing. The line-up of products; resolvers, motors, skew sensors, wingtip position units, flap/slat control levers and power drive unit motors.

Integrated Manufacturing

included Special Process

Tamagawa has the ability to make small size and precious machining depending on experience of defense and general industry production. Many Machining Centers are available in group company and the machining ability is in highest level in Japan.

Airworthiness Design

Technology

Tamagawa is provides commercial off-the-shelf (COTS) products in various kind of industries. Based on standard models of many types of motors, frameless/built-in resolvers and VR resolvers, modification can be offered in accordance with your systems.