AVIATION SAFETY

Various kinds of environmental testing for Aircraft Equipment

March 18, 2021

March 18, 2021

S-BIRD, the environmental test facility is located in 15 minute’s drive from Tamagawa Seiki Co., Ltd.

This facility was created with the aim of advancing and realizing the added value of aircraft and other industries in Iida region through the cooperative efforts of organizations in Nagano Prefecture / Japan.

This article focuses on the “Temperature / Altitude / Humidity Icing Test Chamber” and “Flammability and Fire-resistance Testing Equipment” at S-BIRD.

Temperature/Altitude/Humidity Icing Test Chamber

Temperature / Altitude / Humidity Icing Test Chamber

Reproduce altitude 52,000 feet

Temperature / Altitude / Humidity Icing Test Chamber evaluates the safety and reliability of aircraft equipment. This test chamber is like a huge refrigerator capable of adjusting barometric pressure. It reproduces barometric pressure, temperature and humidity of an aircraft, taking off through landing, inside the tank. Compare to the Explosion Proof Test Chamber featured in the previous issue, the characteristics of this test chamber is its ability to reproduce temperature change and low-temperature condition.

This chamber can reproduce altitude equivalent to 52,000 feet (16,000 meters), and change the barometric pressure in the range of 101.3 to 10.7 kPa, the temperature in the range of 100 to -70 degree C, and the humidity in the range of 20 to 90% RH.

Conform to RTCA DO-160G

Test standards comply with RTCA DO-160G Sec.24 and Japanese Industrial standards, JIS W 0812 (Airborne equipment - Environmental conditions and test procedures). Icing testing has not complied with DO-160G at this time but has basic specifications and enables testing if adds some optional functions such as spraying.

Based on Tamagawa’s advices

This test chamber is manufactured by a major environmental equipment manufacturer in Japan, Espec Corporation in Osaka. Tamagawa gave full support to its implementation planning and advised on the specifications as a main advisor of the working group.

This test chamber was introduced at S-BIRD in 2017 and Tamagawa frequently uses this test chamber for qualification / verification testing for sensors, motors, actuators and levers. Japan Aerospace Exploration Agency (JAXA) also has a similar testing chamber, but in terms of the public accessibility, this test chamber at S-BIRD is the largest test chamber in Japan.

Specifications

| Model Number | MZH-35S-H |

|---|---|

| Test Standard | RTCA DO-160G Sec.24 Category B |

| Barometric Pressure Range | 101.3 to 10.7 kPa (Atmospheric Pressure / Altitude 52,000 ft equivalent) |

| Temperature Range | -70 to 100 degree C (Atmospheric Pressure), -60 to 100 degree C (10.7 kPA to Atmospheric Pressure) |

| Humidity Range | 20 to 95 % RH |

| Inside Dimensions of Tank | W1,500 x H1,500 x D4,000 mm |

| Outside Dimensions of Tank | W3,380 x H2,835 x D5,100 mm |

| Remarks | Skydrol (a fire-resistant aviation hydraulic fluid) resistant; Slide conveyor for specimen |

Flammability and Fire-resistance Testing Equipment

Prevent fire in aircraft and secure time for evacuation

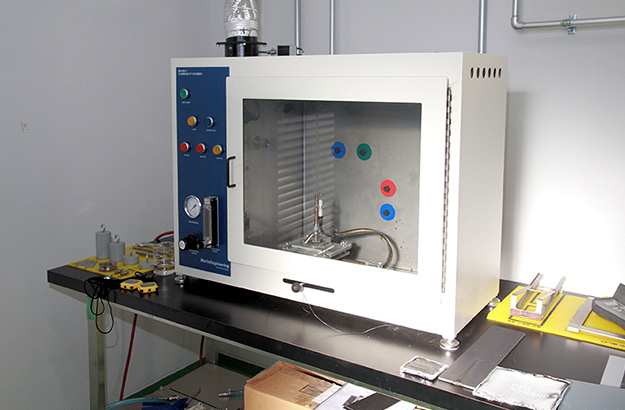

There is 8 different chambers for flammability and fire-resistance testing at S-BIRD. All of these chambers are manufactured by Merlin Engineering (USA). In Japan, they are the only public chambers specialized in aircraft equipment.

Federal Aviation Administration (FAA) established regulations that all passengers and crewmembers can be evacuated within 90 seconds in an emergency. It is necessary for aircraft equipment not only to have fire resistance but also to suppress the smoke and toxic gas generation.

Flammability Chamber

Evaluate the flame-spread rate and self-extinguishing properties of specimen.

Heat Release Chamber

Evaluate the heat release value of specimen.

Smoke Density Chamber

Evaluate the smoke generation of specimen.

Toxicity Analysis Kit

Analyze the toxic gas components emitted from combustion of specimen.

Vertical Flame Propagation Chamber

Evaluate the flammability of insulation material.

Radiant Panel Chamber

Measure the heat radiated from the panel.

Sonic Burner

Evaluate the flame resistance of specimen, such as seat cushions, cargo liners, magnesium parts, insulation near engine exhaust.

Conditioning Chamber

Equalize the temperature and humidity.

Don’t miss it!!

Introduction in next Newsletter

OUR TECHNOLOGIES CAN HELP YOUR DEVELOPMENT

Commercial Aircraft Applications

Tamagawa supplies many variety of products for commercial aircraft applications for Cockpit Control, High Lift System, Primary Flight Control System, Weather Radar, Steering System and Engine System, etc.

Business Jet Applications

Tamagawa supplies various kind of products for business jet applications for Door Actuator, Landing Gear System, Flight Control System, Cockpit Lever, Weather Radar and Throttle Quadrant Assembly, etc.