Nadcap Accredited:

Aerospace Special Processes

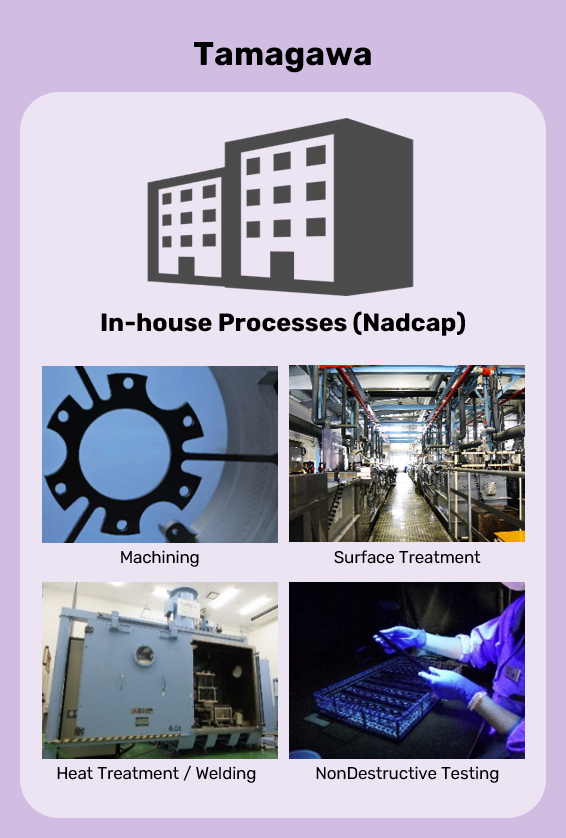

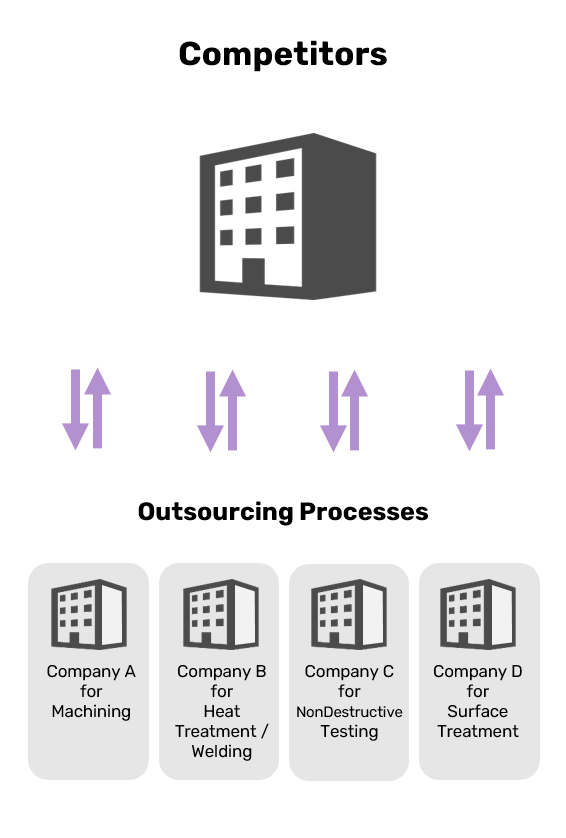

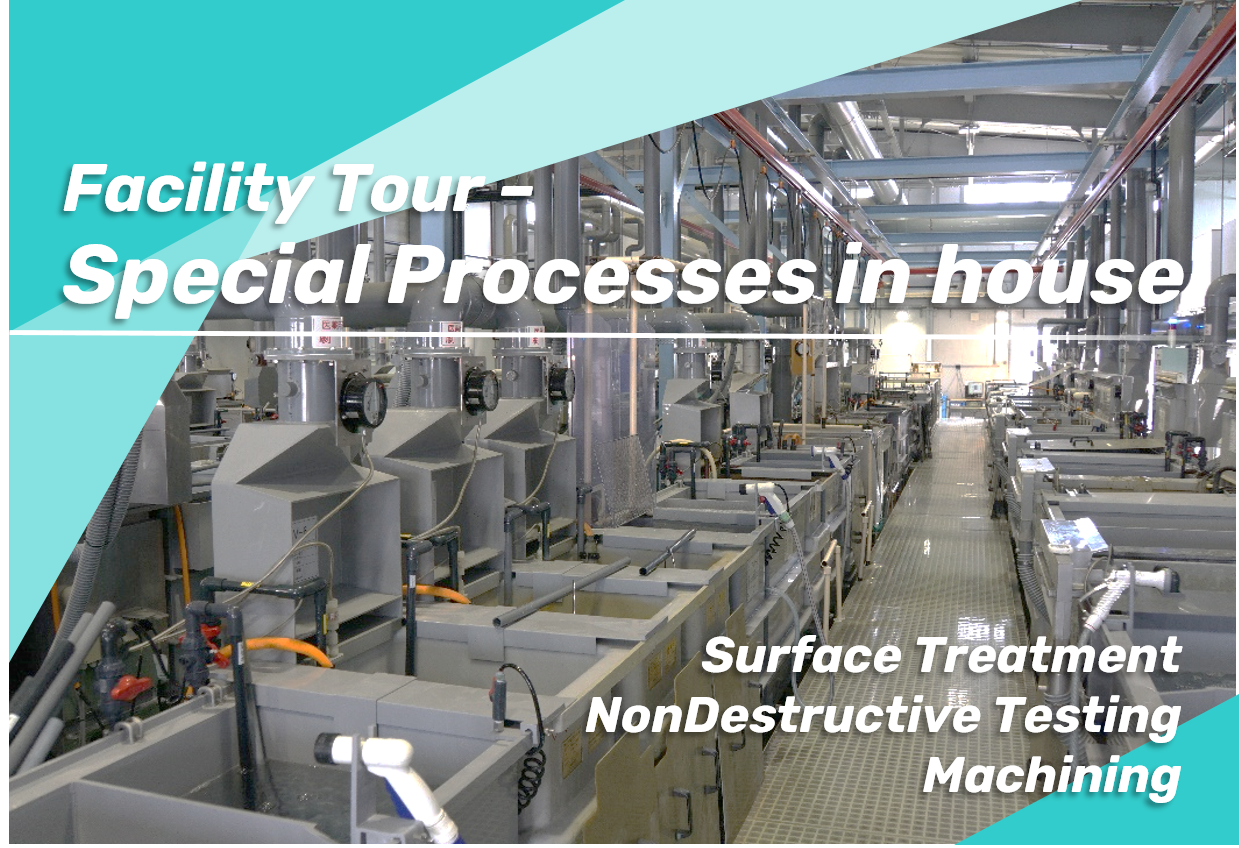

Integrated Manufacturing at Tamagawa

Special Processes are essential to Aerospace products. Tamagawa Group breaks away from the conventional way of outsourcing processes and enables integrated manufacturing in house with Nadcap accreditation.

September 15, 2021

September 15, 2021

01. Integrated Manufacturing

Tamagawa Group Company

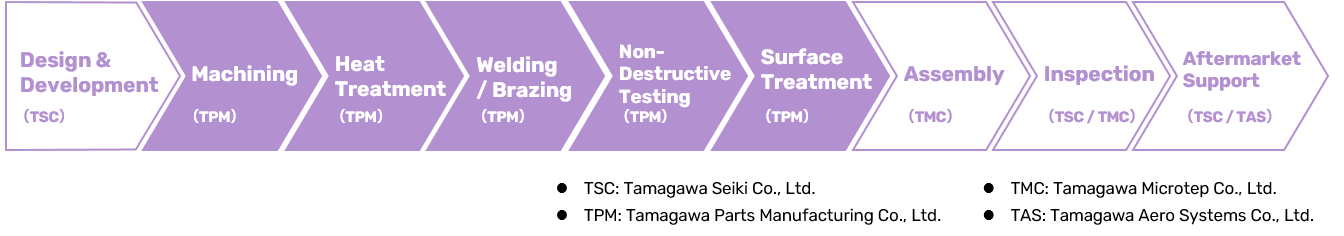

Tamagawa Group has an integrated process from Design & Development, Special Processes, Assembly to Inspection and Aftermarket Support. This in-house processes achieve not only shorter lead time but also cost-effective manufacturing. These advantages meet customer’s expectations of expedited delivery and reasonable product pricing.

Tamagawa Parts Manufacturing Co., Ltd. (TPM)

Tamagawa Parts Manufacturing Co., Ltd. (TPM) is a subsidiary wholly-owned by Tamagawa Seiki Co., Ltd. and was founded by spinning off the Machining Department and the Special Process Department of Tamagawa Seiki Co., Ltd. into a separate company.

The facility was established by government funding and it was one of the big projects to enhance the Aerospace business in this region.

02. Heat Treatment

Heat Treatment

Heat Treatment is a processing technology that changes the properties of a metal material without changing its shape by heating and cooling. For example, strength, hardness, tenacity, impact resistance, wear resistance, corrosion resistance, machinability and cold workability, etc.

Nadcap Certificate for Heat Treating

Gas quenching furnace / Tempering furnaces

Classification of Heat Treatment Processes

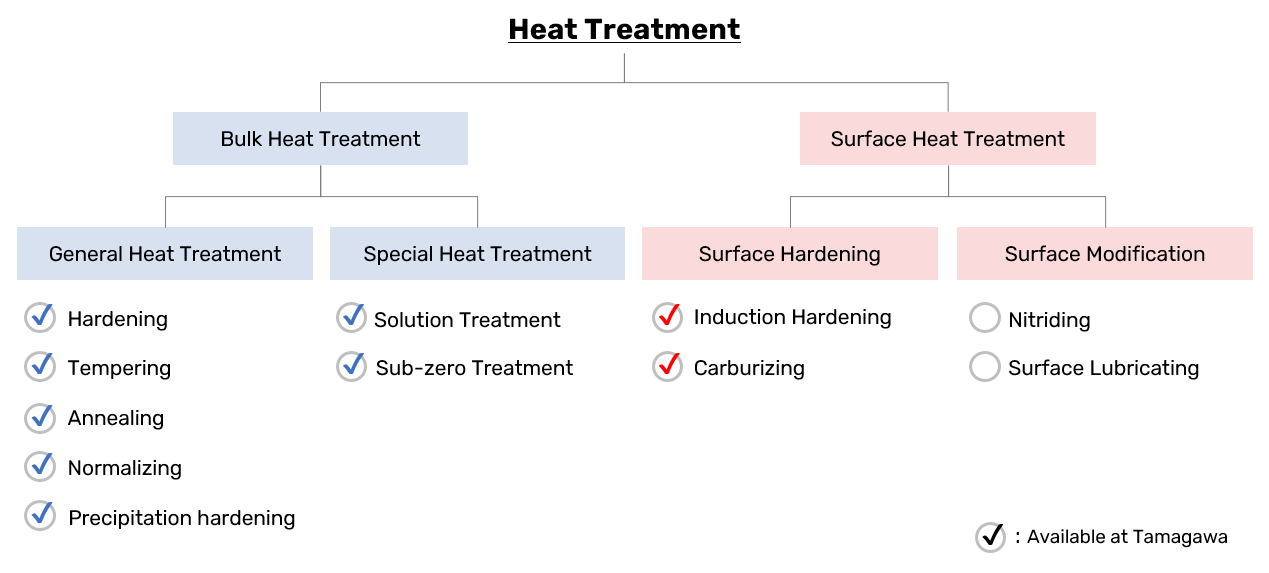

Heat Treatment can be divided into two main categories: Bulk Heat Treatment and Surface Heat Treatment. “Bulk Heat Treatment” changes the characteristics of the entire material, while “Surface Heat Treatment" changes the properties of only the surface of the material.

The four basic types of Heat Treatment are Hardening, Tempering, Annealing, and Normalizing, which are classified as General Heat Treatment in Bulk Heat Treatment.

- Hardening

- A process to harden steels by raising the temperature to a certain level, and then cooling it rapidly.

- Tempering

- A process to increase tenacity and toughness of steels. It is performed in combination with Hardening.

- Annealing

- A process to soften steels for easy processing.

- Normalizing

- A process to homogenize and refine the structure of steels.

Carburizing is a process that provides high surface hardness and high core toughness with materials. It is mainly applied to gears and shafts which required these characteristics.

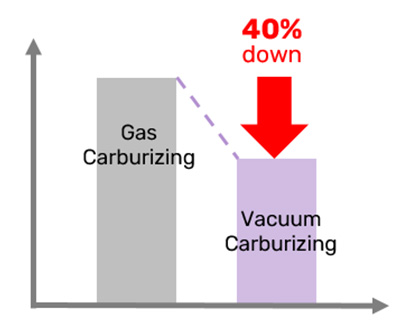

Gas Carburizing is the most usual process, but in recent years, demand for Vacuum Carburizing is increasing in Aerospace industry.

Advantages of Vacuum Carburizing

Prevent oxidation of the material surface

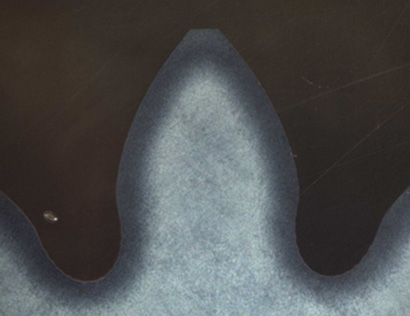

Vacuum Carburized Gear parts

Speedup of Carburizing by 40%

(Compare to Gas Carburizing)

Vacuum Carburizing Furnace

Heat Treatment at Tamagawa

| Description | Materials | Applicable Specification |

|---|---|---|

| Hardening Annealing Solution Treatment Tempering Precipitation Hardening |

Carbon / Alloy Steel Stainless Steel |

AMS2750 AMS2759 AMS2769 |

| Sub-zero Treatment | AMS2750 AMS2759 |

|

| Carburizing | Carbon / Alloy Steel |

Heat Treated Products

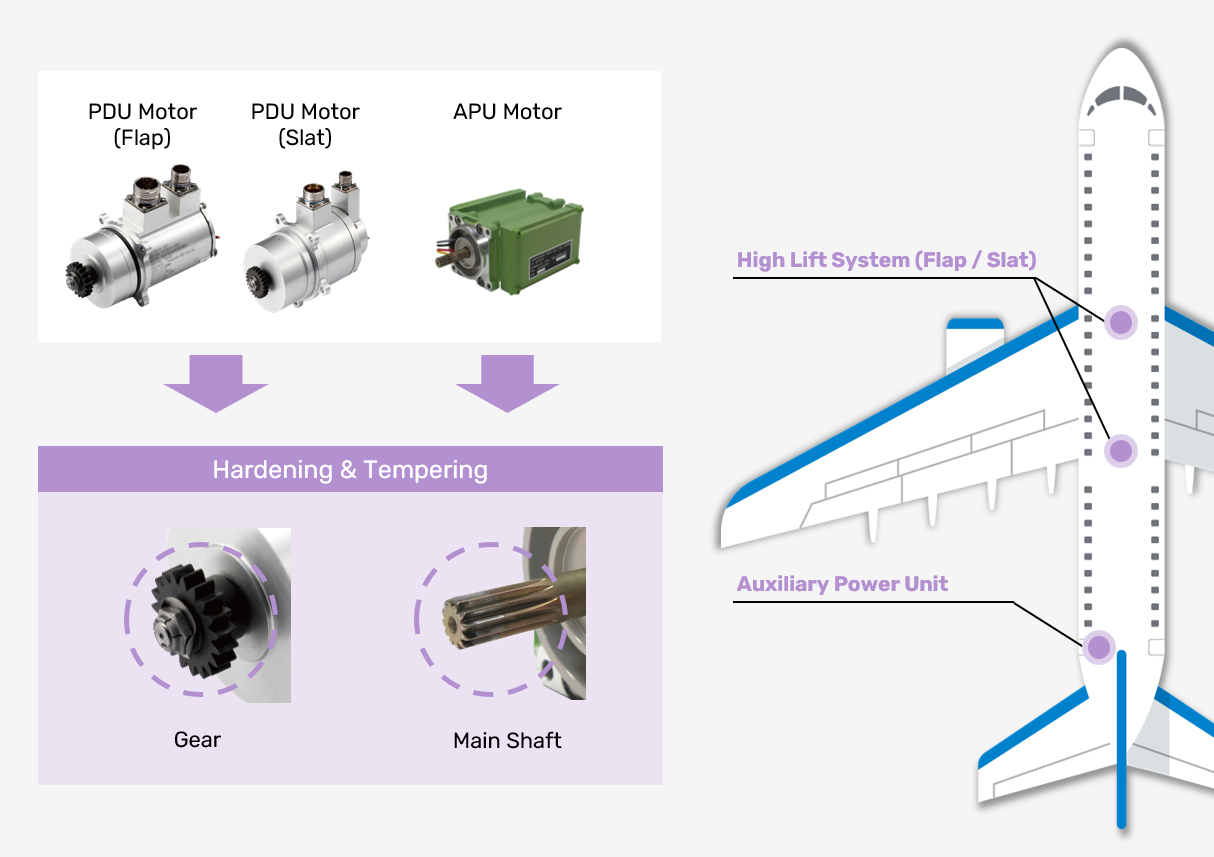

Tamagawa Motors used for High Lift System and Auxiliary Power Unit (APU) are heat treated by Hardening and Tempering. For example, Gear of Power Drive Unit (PDU) Motors and Main Shaft of APU Motors.

03. Welding / Brazing

Nadcap Certificate for Welding

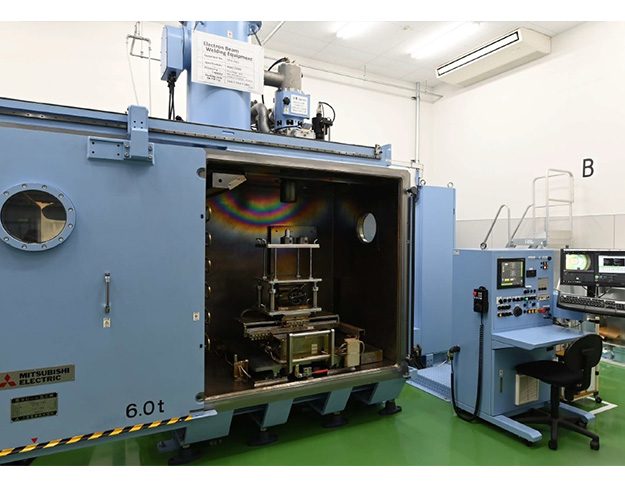

Electron Beam Welding Machine

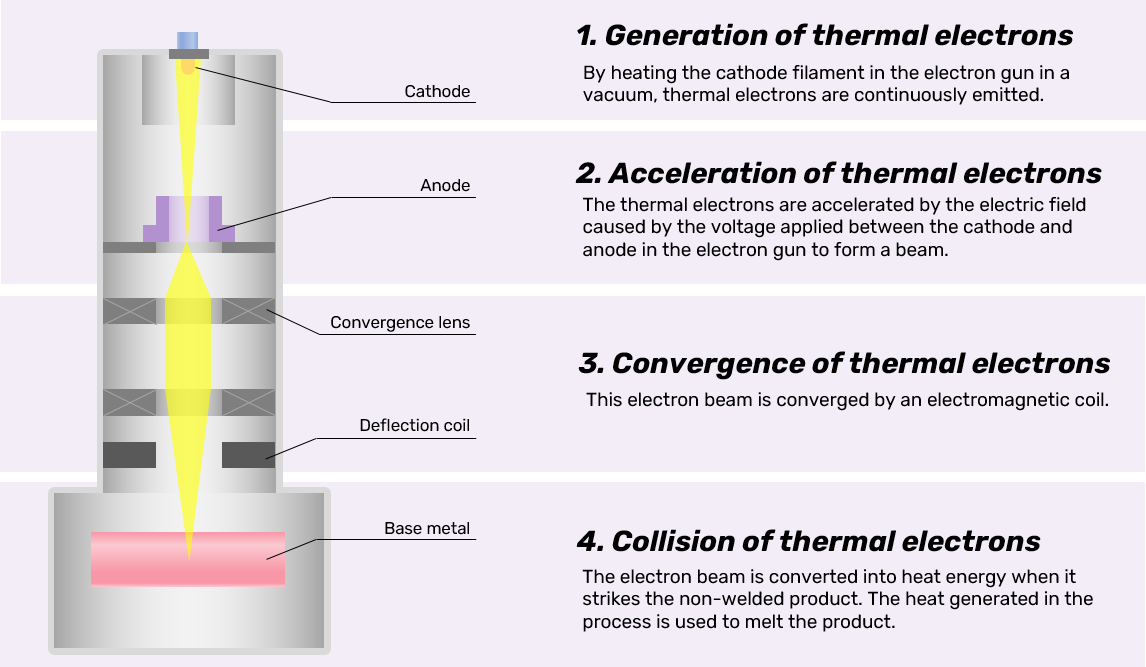

Electron Beam Welding (EBW)

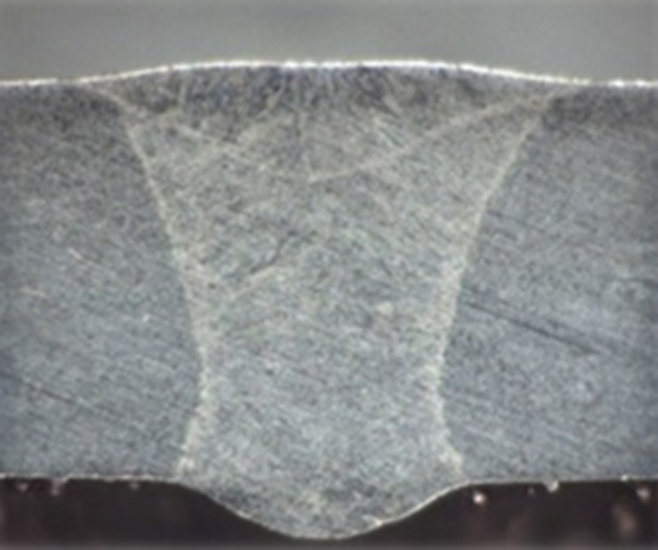

Electron Beam Welding is the joining method by melting base metal. The weld strength is close to the strength of the base metal itself.

With high energy level, Electron Beam Welding can produce thin and deep joints. In this case, the heat effect on the parts is small and the weld deformation is small. The weld width can be adjusted and the weld position can be controlled using a numerical control program, which can be used for complex welds.

Penetration Welding / INCONEL

(Depth: 12.6 mm)

Piercing Welding / 15-5PH

(Thickness: 3 mm)

There are five EBW Nadcap accredited companies in Japan. Three of five are heavy industries companies and one of the remaining two companies is Tamagawa. After the process of EBW, NonDestructive Testing is usually required to be conducted. Except for major heavy industries companies, Tamagawa is the only company in Japan which can conduct all necessary NonDestructive Testing with all of it’s Nadcap accreditation. This rare exception is a big advantage for Tamagawa in terms of the easiest accessibility.

Tamagawa can complete entire processes including EBW and NonDestuctive Testing in house and ensure quick turnaround.

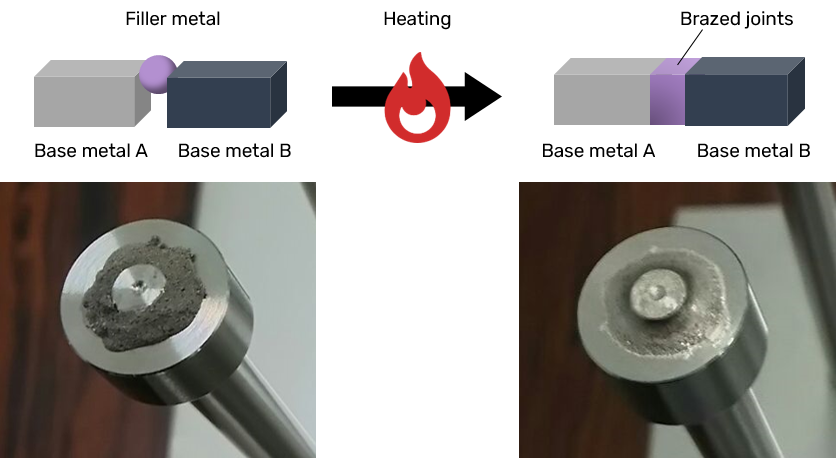

Brazing

Unlike EBW, Brazing use filler metal without melting base metal during the joining process.

There are two types of Brazing method. “Soldering” is defined in case the melting point of the filler material is 450 degree C or lower, and “Brazing” is defined in case the melting point is higher.

Welding / Brazing at Tamagawa

| Description | Materials | Applicable Specification |

|---|---|---|

| Electron Beam Welding | Carbon / Alloy Steel Stainless Steel Nickel Base Superalloy |

AMS2680 AMS2681 |

| Brazing (Torch Brazing & Furnace Brazing) |

Carbon / Alloy Steel Stainless Steel Copper Alloys |

AWS C3.4M / C3.4 AWS C3.6M / C3.6 |

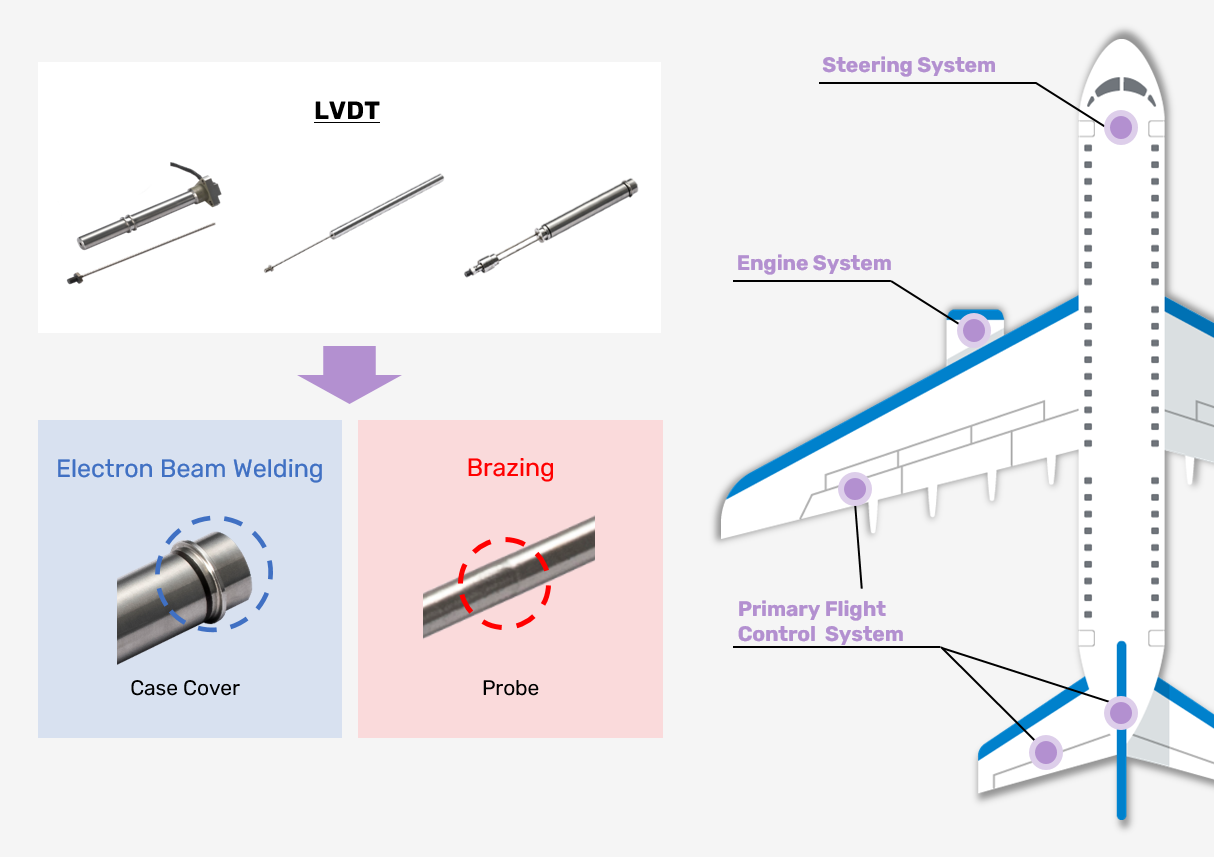

Welded / Brazed Products

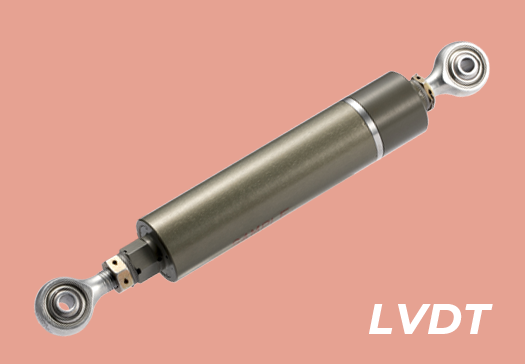

Tamagawa LVDTs used for Steering System, Engine System and Primary Flight Control System are welded by Electron Beam Welding / Brazing. For example, EBW for Case Cover and Brazing for Probe.

Don’t miss it!!

Introduction in next Newsletter

OUR TECHNOLOGIES

CAN HELP YOUR DEVELOPMENT

LVDT

Tamagawa LVDT is the standard linear position sensor for Flight control, Cockpit/Pilot control, EHSV (Electrohydraulic Servo Valve), Engine Valve applications, Fuel control and others.

Brushless DC Motor + Brake + Sensor

This type of Tamagawa Motor integrates electric brake and feedback angular sensor like Hall IC or Resolver. Typical applications are for power drive unit and actuation and motion control systems.