Have you ever tried “Electro Mechanical” Actuator?Actuation Systems for Aircraft can be Electrified with our EMA

Tamagawa Seiki Co., Ltd. is a well-experienced manufacturer of Electro Mechanical Actuators (EMA) especially for Business Jet applications.

According to the times of Aircraft Electrification, Tamagawa is focusing on the research and development of EMAs more than ever.

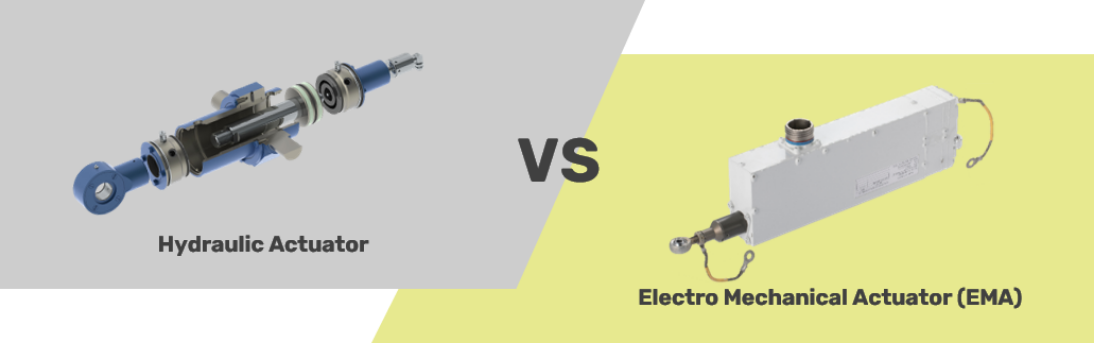

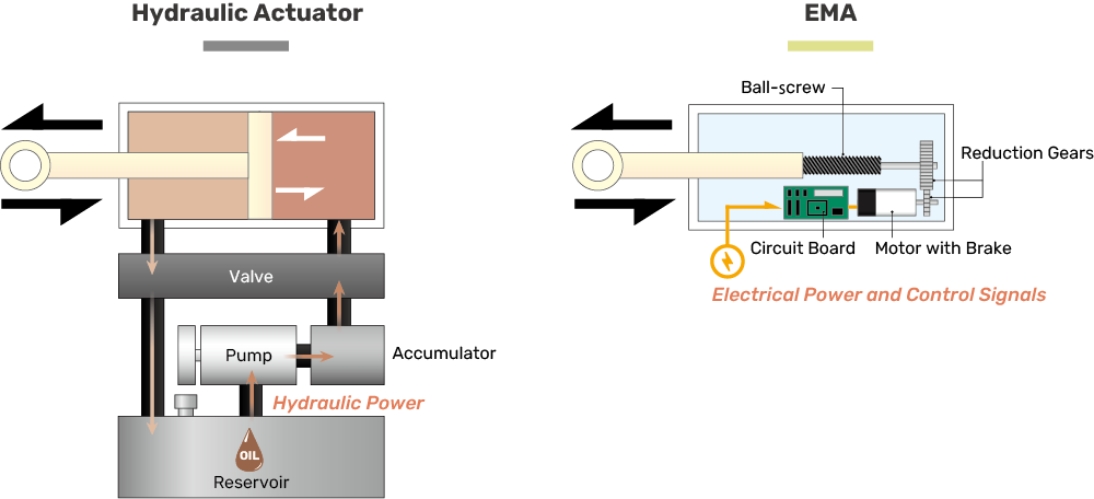

01.Hydraulic Actuator vs Electro Mechanical Actuator

An Actuator is a component that moves / controls a system by converting energy into mechanical motion. For the use of Aircraft applications, the main sources of energy are hydraulic pressure (Hydraulic Actuator) and an electric current (Electro Mechanical Actuator).

| Hydraulic Actuator | Electro Mechanical Actuator (EMA) | |

|---|---|---|

| Characteristics | High Power | High Confluence with Electronics & Computer |

| Weight | Heavy Weight (Including Plumbing) |

Light Weight (Pluming-free) |

| Compact | Space-consuming | Space-saving |

| Maintainability | Frequent Maintenance Required (Oil leakage & Complicated Plumbing) |

Less Maintenance |

| Precise | Difficult to control closely | Easy Control & Better Performance (Position & Speed) |

| Power Source | Hydraulic Pressure (Engine) |

Electric Current (Motor) |

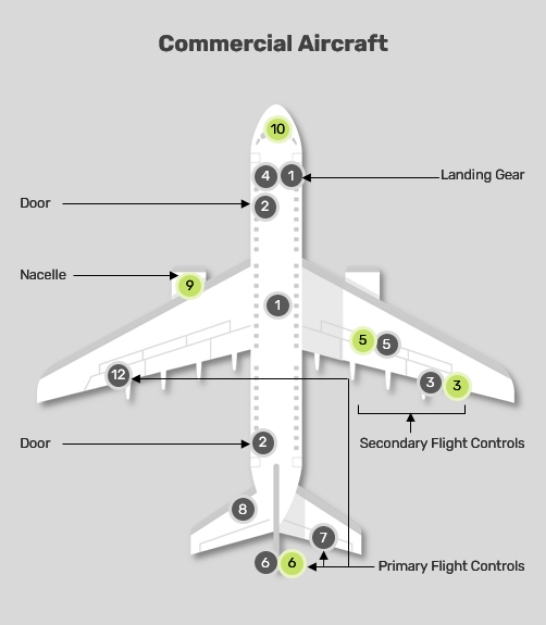

02.Aircraft Applications of EMAs

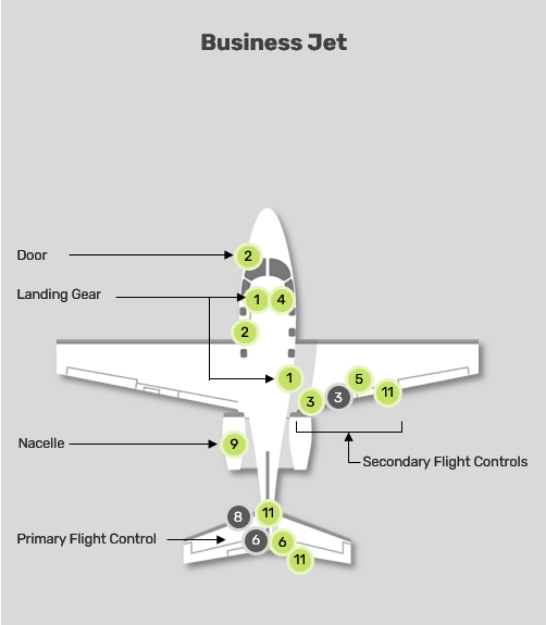

In these days, an increasing number of EMAs for Aircraft applications take a role as alternates of Hydraulic Actuators. Focusing on Business Jets, transition to EMAs is markedly going on with the advantages contributing Aircraft Electrification and Carbon Neutral Flight.

- : Hydraulic Actuator

- : Electro Mechanical Actuator (EMA)

- ① Landing Gear Actuator

- ② Door Actuator

- ③ Flap Actuator

- ④ Nose Wheel Steering Actuator

- ⑤ Spoiler Actuator

- ⑥ Rudder Actuator

- ⑦ Elevator Actuator

- ⑧ Horizontal Stabilizer Trim Actuator (HSTA)

- ⑨ Nacelle Door Actuator

- ⑩ Auto Pilot Control Actuator

- ⑪ Trim Tab Actuator

- ⑫ Aileron Actuator

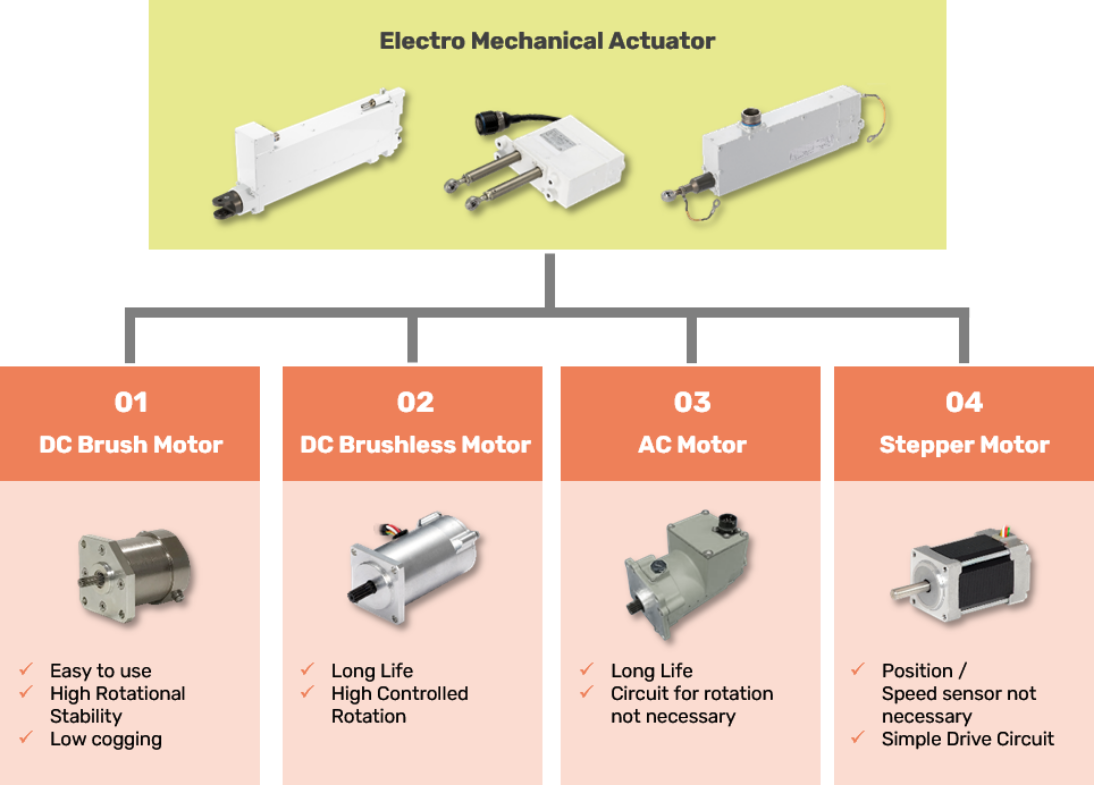

03.Motors integrated in EMAs

Tamagawa also has an ability to manufacture the integrated Motors inside of Actuators. Motors are selected according to the control methods, operational methods, and endurance.

Including these kinds of Motors, the structure / configuration of EMAs have been upgraded to satisfy various kinds of requirements.

OUR TECHNOLOGIES

CAN HELP YOUR DEVELOPMENT

RVDT Cluster

TAMAGAWA RVDT Cluster with integrated gears is angular position sensor unit, equipped with maximum 5 RVDTs in the shell to realize redundancy.

Brushless DC Motor + Brake + Sensor

This type of Tamagawa Motor integrates electric brake and feedback angular sensor like Hall IC or Resolver. Typical applications are for power drive unit and actuation and motion control systems.