Landing Gear Actuator: How does it work?Emergency Release Mechanism of our EMA saves your lives

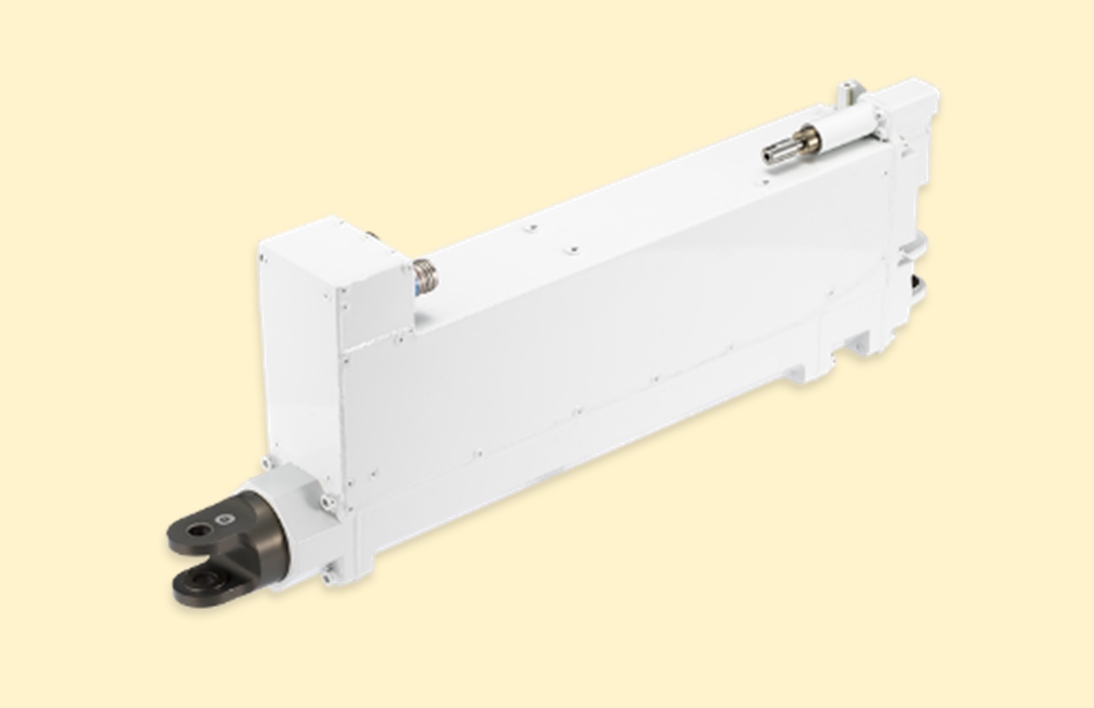

Aviation Safety is our earnest desire. Electro-Mechanical Landing Gear Actuator which has been designed and manufactured at Tamagawa Seiki Co., Ltd. can support your Landing Gear Systems to fulfill safe flight.

01.“Electro-Mechanical” Landing Gear Actuator

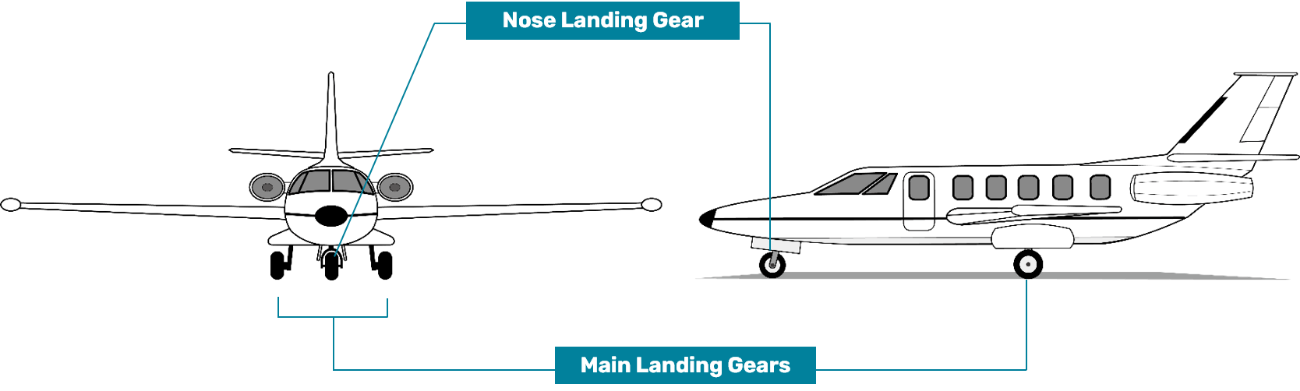

Electro-Mechanical Landing Gear Actuator nowadays has the ability to generate higher torque than it used to be. That is the main reason Hydraulic Landing Gear system for Business Jets is being replaced to Electric system. Electro-Mechanical Landing Gear Actuator makes less noise and saves weights than Hydraulic Actuator.

PC-24 Landing (Credit: Pilatus Aircraft Ltd)

PC-12 Landing Gear Actuator (Credit: Pilatus Aircraft Ltd)

Design Options

- Mechanical Interface: Spherical Bearing or Cardan Joint

- Heater: Can be integrated for high altitudes (low temperature)

- Combination: Extend / Retract (Actuator) & Up / Down (Landing Gear)

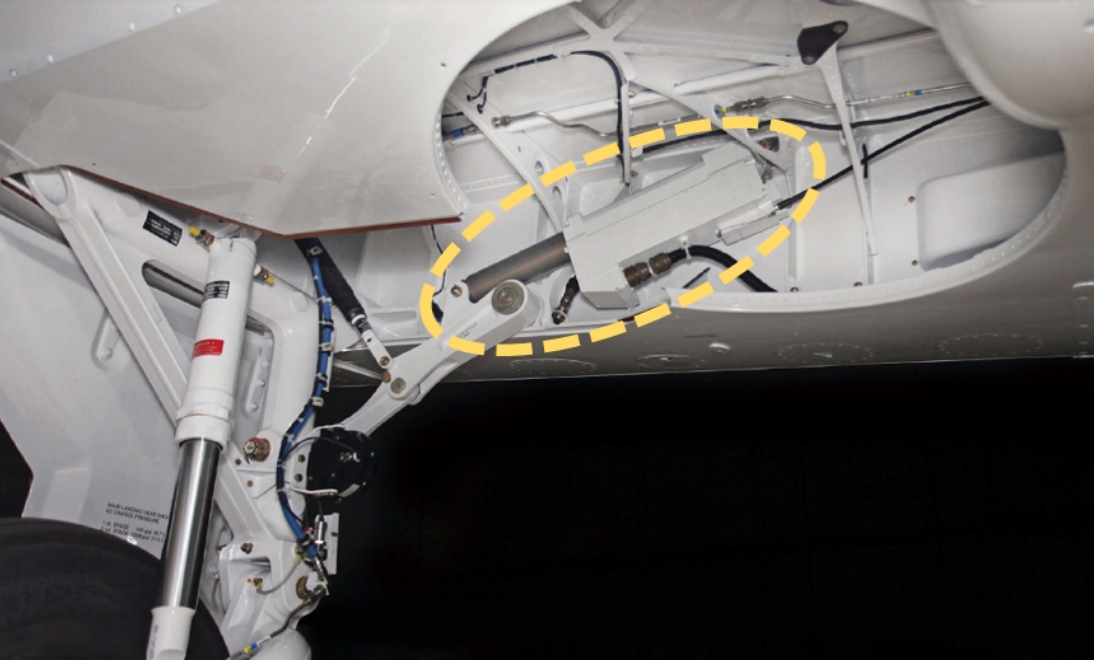

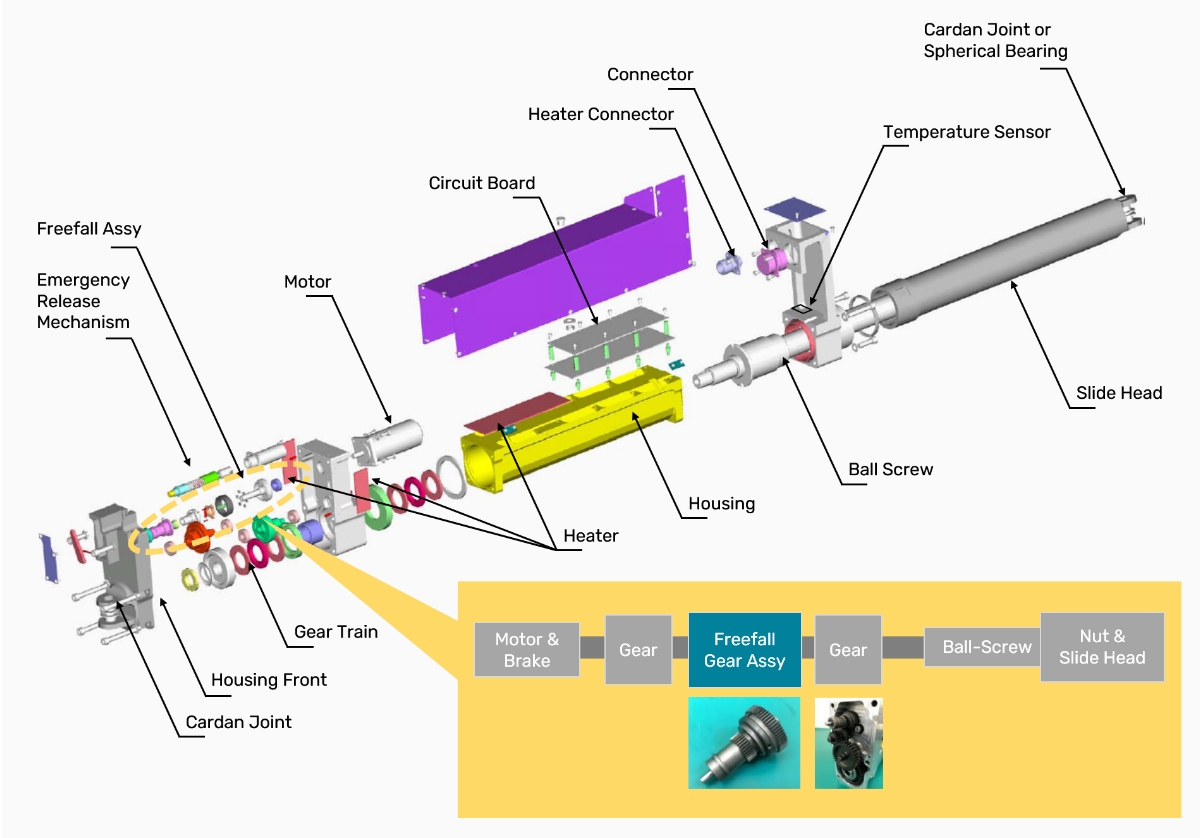

02.Emergency Release Mechanism

Tamagawa Electro-Mechanical Landing Gear Actuator has an emergency system that is activated when Aircraft loses power or when Actuator stops in the middle of deploying. When the pilot pulls the “emergency lever," Actuator rod becomes free and the legs deploy (called “Freefall”).

Freefall Gear Assy Movement

Following 3D animation explains the Emergency Release Mechanism.

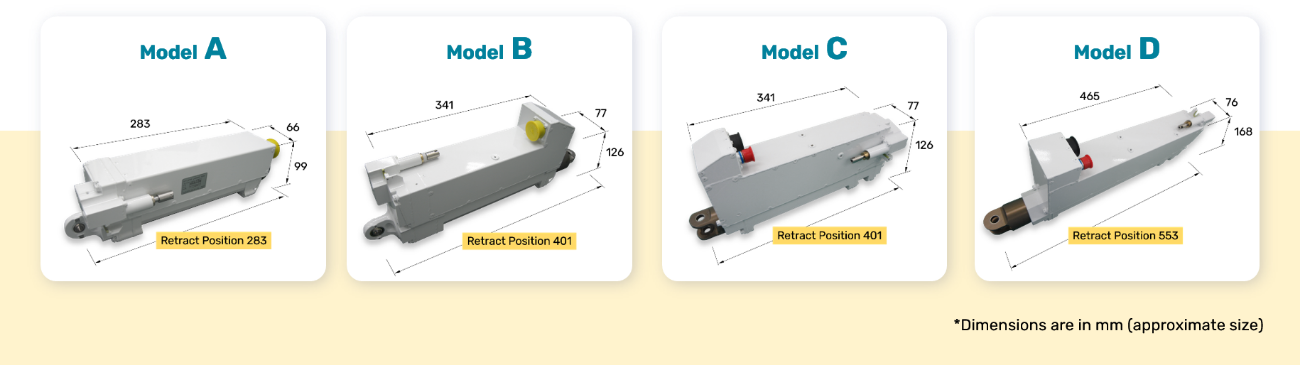

03.Lineup – Electro-Mechanical LGA

Tamagawa is one of the leading supplier of Electro-Mechanical Landing Gear Actuators and builds a close relationship with customers, especially for Business Jets. We always focuses on discussion with customers and propose best fitted envelope, mechanical interface and load capability which satisfies customer’s requirements.

| Model Number | Model A | Model B | Model C | Model D |

|---|---|---|---|---|

| Usage | NOSE | MAIN | NOSE | MAIN |

| Type | Linear | Linear | Linear | Linear |

| Operating Load | 7,000 N (1,573 lbf) |

16,000 N (3,596 lbf) |

16,000 N (3,596 lbf) |

12,000 N (2,697 lbf) |

| Pre Load | 12,000 N (2,697 lbf) |

12,000 N (2,697 lbf) |

22,000 N (4,945 lbf) |

27,000 N (6,070 lbf) |

| Limit Load | 17,200 N (3,867 lbf) |

34,000 N (7,643 lbf) |

36,502 N (8,206 lbf) |

31,888 N (7,169 lbf) |

| Ultimate Load | 25,800 N | 51,000 N | 49,775 N | 43,483 N |

| Retract | 333 mm | 400.45 mm | 405.7 mm | 540 mm |

| Extend | 495 mm | 585.9 mm | 591.15 mm | 840 mm |

| Stroke | 162 mm (6.4 in) |

185.45 mm (7.3 in) |

185.45 mm (7.3 in) |

300 mm (11.8 in) |

| Weight | 3,250 g | 5,750 g | 6,000 g | 8,000 g |

| Speed | 16.2 mm / sec (0.6 in / sec) |

18.5 mm / sec (0.7 in / sec) |

15.5 mm / sec (0.6 in / sec) |

25.0 mm / sec (1.0 in / sec) |

| Power Supply | DC 28 V 23 A Max |

DC 28 V 45 A Max |

DC 28 V 45 A Max |

DC 28 V 45 A Max |

| Operating Temperature | -55 to +70 degC (-65 F to 160 F) |

-55 to +70 degC (-65 F to 160 F) |

-55 to +70 degC (-65 F to 160 F) |

-55 to +70 degC (-65 F to 160 F) |

| Load x Speed | 113.4 W | 296.7 W | 247.3 W | 300.0 W |

Tamagawa has FAA Part 145 Repair Station as a subsidiary company, TAMAGAWA AERO SYSTEMS Co., LTD. (TAS).

The main facility is located in Tokyo, Haneda Airport and we have 70 years experience in MRO of Aircraft component.

Tamagawa Electro-Mechanical Landing Gear Actuators can be repaired and tagged with FAA 8130-3 Form at this Repair Station.

OUR TECHNOLOGIES

CAN HELP YOUR DEVELOPMENT

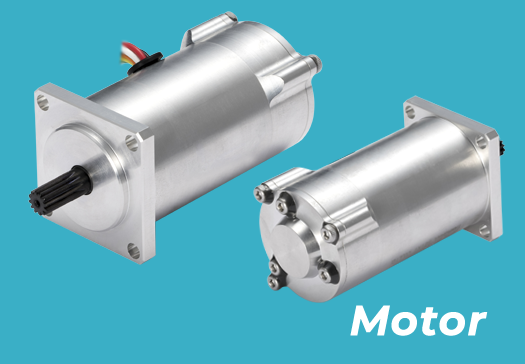

Brushless DC Motor + Brake + Sensor

This type of Tamagawa Motor integrates electric brake and feedback angular sensor like Hall IC or Resolver. Typical applications are for power drive unit and actuation and motion control systems.

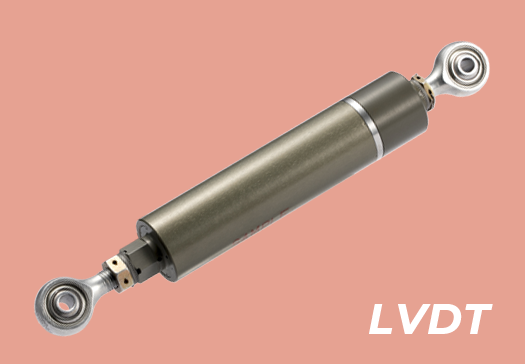

LVDT

Tamagawa LVDT is the standard linear position sensor for Flight control, Cockpit/Pilot control, EHSV (Electrohydraulic Servo Valve), Engine Valve applications, Fuel control and others.