Why choose “RVDT”?

The reason why RVDTs perfectly fit for Aircrafts

May 18, 2021

May 18, 2021

Tamagawa Seiki Co., Ltd. is a well-experienced manufacturer of RVDTs for Aircrafts.

This article discloses the essence of RVDTs; Highly Reliable, Long Life and Smaller & Lighter.

01. Special Features

The reason why RVDTs perfectly fit for Aircrafts

High Reliability

- Less number of piece parts and all metallic structure

Long Life

- Long life design enables low failure rate under harsh environment

Smaller & Lighter

- Simple structure enables downsizing, weight saving and low power consumption

02. Environmental Resistance

Comply with RTCA DO-160G & MIL-STD-810

According to DO-160G and MIL-STD-810, RVDTs have been tested and demonstrated their reliability in various kinds of environmental conditions, such as vibration, shock and temperature variation.

The key to the environmental resistance is their simple and all-metallic structure. This enables RVDTs to work for years with low failure rate and without any specific maintenance.

Environmental testing

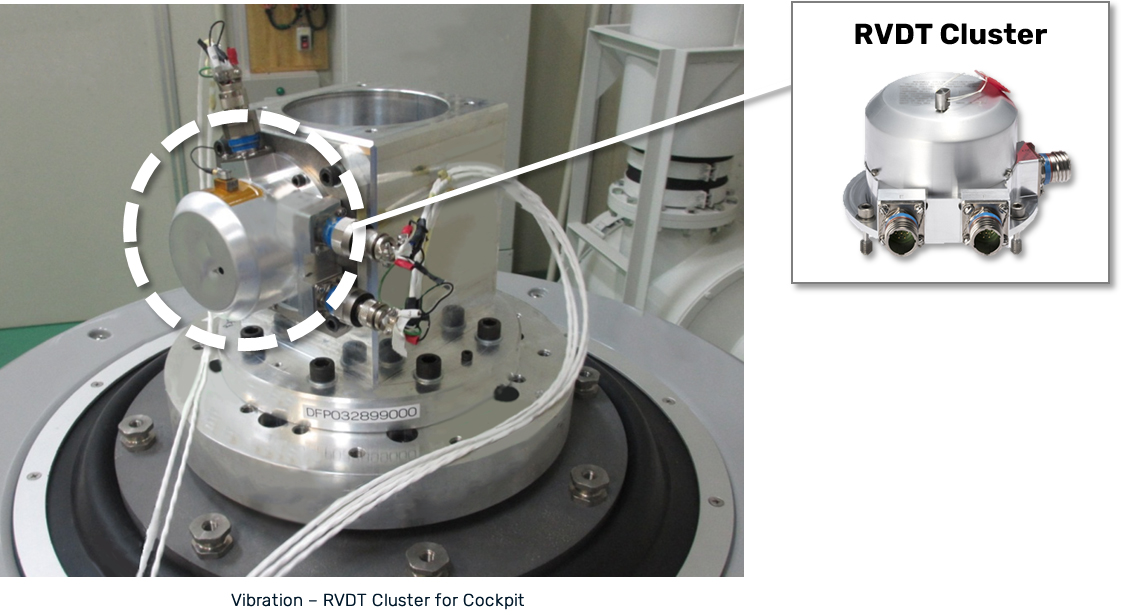

Vibration

These tests demonstrate that the equipment complies with the applicable equipment performance standards (including durability requirements) when subjected to vibration levels specified for the appropriate installation.

(Reference: RTCA DO-160G, Section 8.0, category S)

Environmentally resistant RVDTs which are installed exposed exteriors of Aircrafts have been passed more severe testing, such as Waterproofness, Fluids Susceptibility and Icing, to verify its high reliability.

Waterproofness

These tests determine whether the equipment can withstand the effects of liquid water being sprayed or falling on the equipment or effects of condensation.

(Reference: RTCA DO-160G, Section 10.0, category S)

Fluids Susceptibility

These tests determine whether the materials used in the construction of the equipment can withstand the deleterious effects of fluid contaminants.

(Reference: RTCA DO-160G, Section 11.0, category F)

Icing

These tests determine performance characteristics for equipment that must operate when expose to icing conditions that would be encountered under conditions of rapid changes in temperature, altitude and humidity.

(Reference: RTCA DO-160G, Section 24.0, category B&C)

03. RVDT Lineup

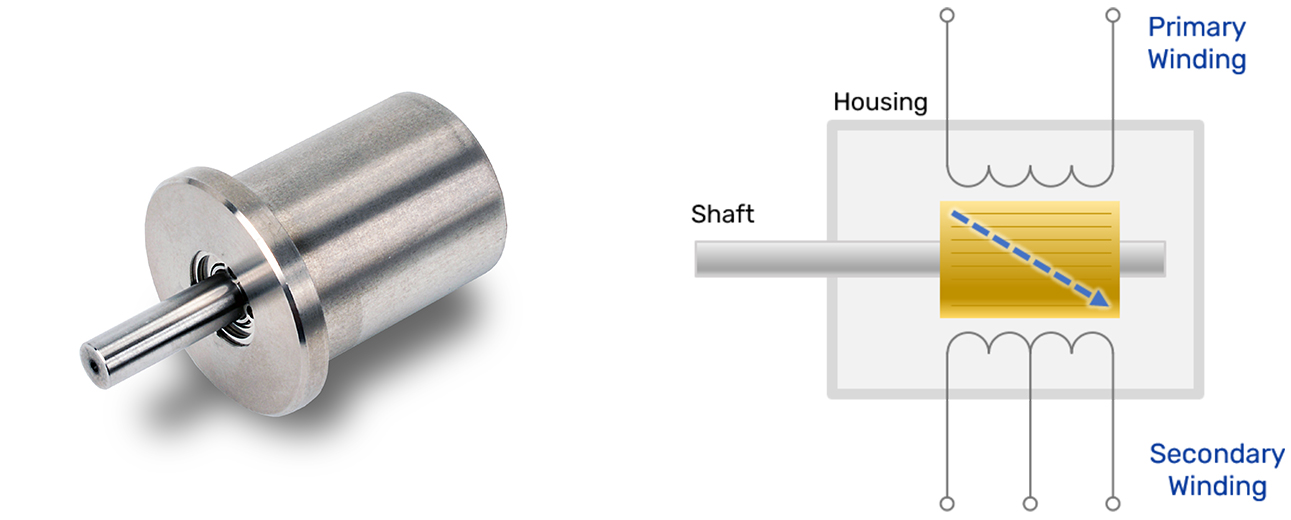

Single RVDT

Basic RVDT which has only 1 channel

Easy to minimize and downsize

General-purpose RVDT

Data Sheet

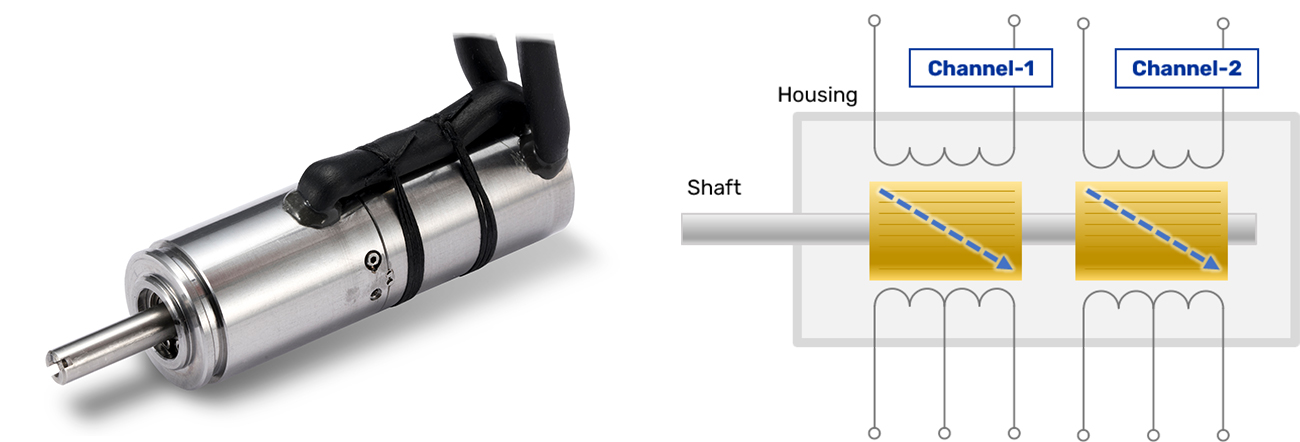

Tandem RVDT

Dual redundant RVDT which has 2 channels on a shaft

Tandem structure simultaneously realizes space-saving and redundancy

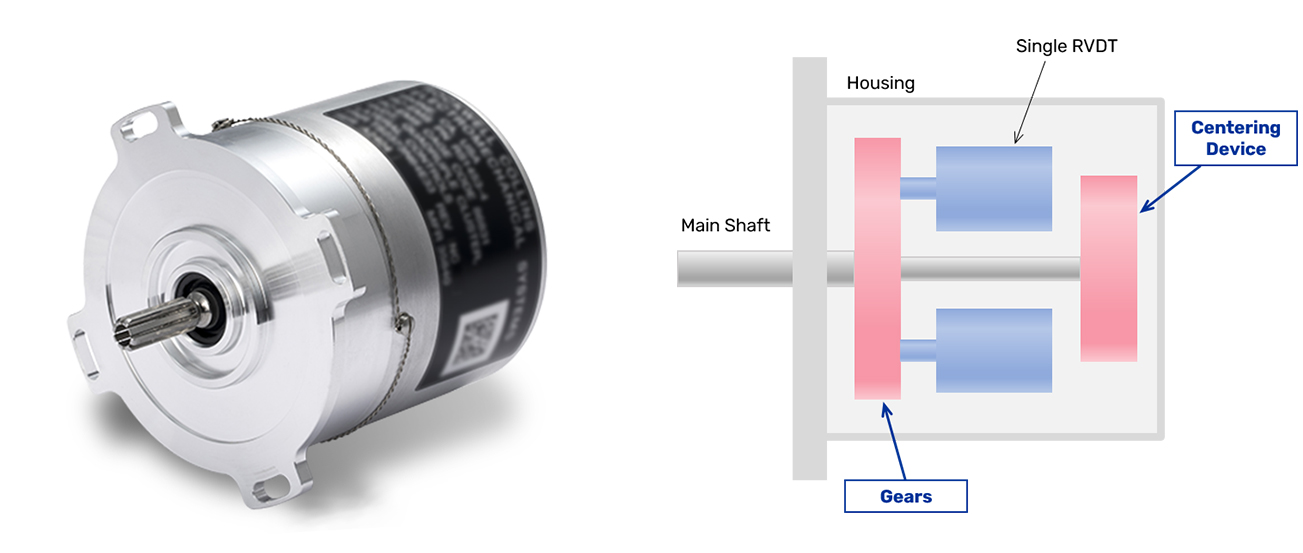

RVDT Cluster

Geared RVDT which integrates multiple single RVDTs

Multiple redundant structure simultaneously realizes higher reliability and high level signal processing with multiple channels outputs

Number of channels can be customized - MAX 5 channels

Customizable gear ratio – the angle detection range of main shaft can be adjusted

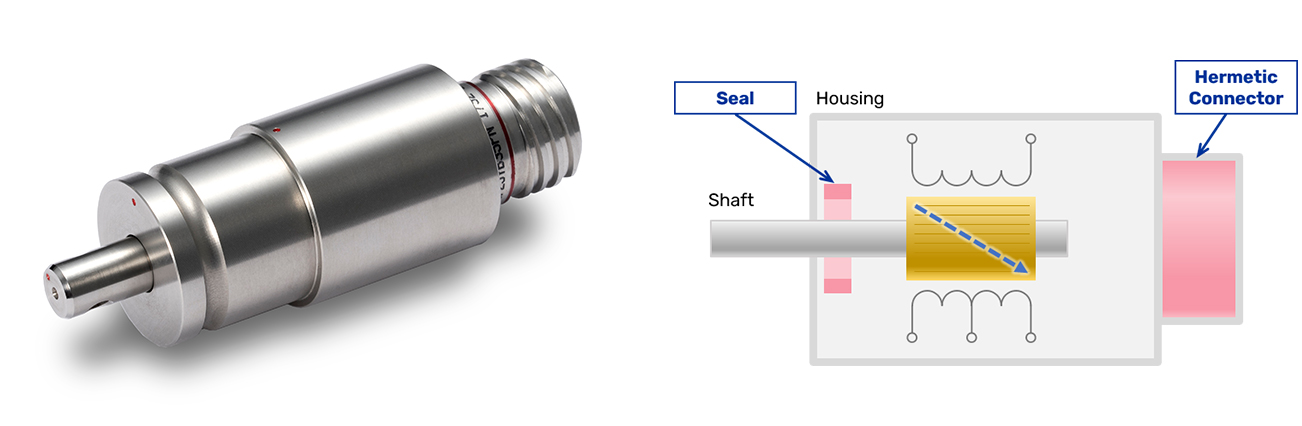

Environmentally Resistant RVDT

Mainly used for Flight Control System which is exposed to outside of aircraft

Great combination of robustness, airtightness and weather-proofness

Better temperature characteristics which accurately works even in the wide range, -55 to 85 degree C

04. Applications

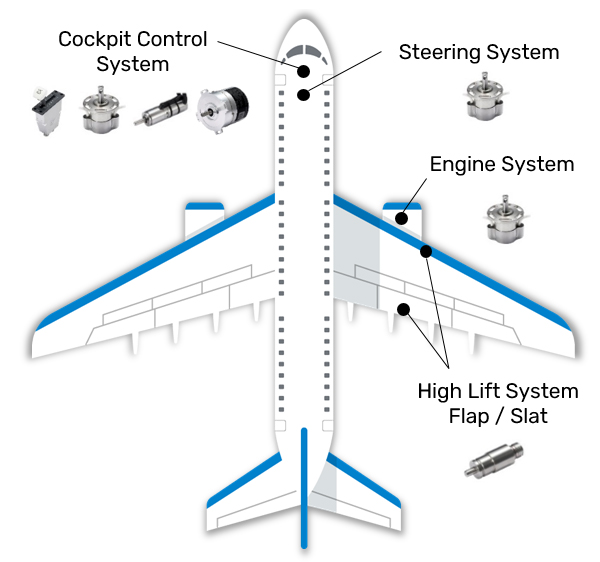

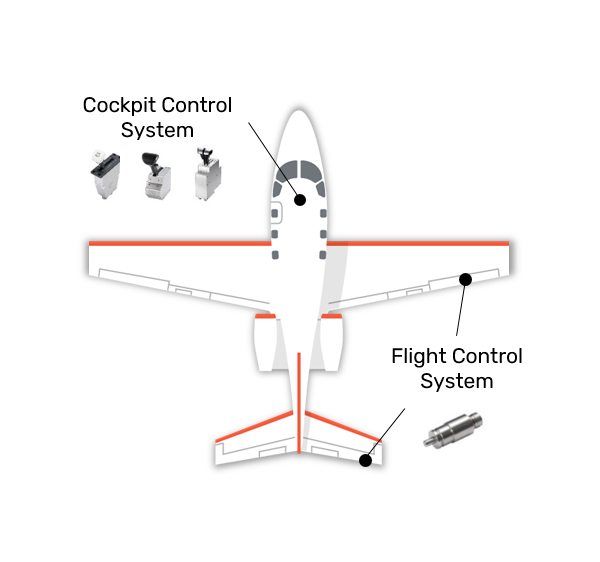

Aircraft systems need RVDTs

Aircrafts consist of various kinds of systems which use angular data as a critical information, such as Cockpit Control System (Control wheel, Throttle lever & Pedal), Flight Control System (Aileron, Rudder & Elevator) and High Lift System (Flap / Slat). For the sake of a safe flight, RVDTs work effectively in detecting angles even in a severe environmental conditions.

Don’t miss it!!

Introduction in next Newsletter

OUR TECHNOLOGIES

CAN HELP YOUR DEVELOPMENT

Motor

Tamagawa provides various kinds of motors like Brushless DC Motor with Integrated Electronics & Gearbox. These Motors are used in Cockpit, High Lift System and Weather Radar, etc.

RVDT

Tamagawa RVDT provides linearly proportional voltages to the angular displacement with high reliability for vibration under extreme low/high temperature. Size 08, 10 and 11 are available in Tamagawa's RVDT series.