Facility Tour –

Special Processes in house

Eco-Friendly Technologies & Facility

Taking advantage of experience and technology through the long history, Tamagawa Group is accelerating great efforts to realize the advanced eco-friendly manufacturing. This approach satisfies not only customer’s requirements but also social trend asking for environmental consciousness.

October 14, 2021

October 14, 2021

01. Surface Treatment

Surface Treatment

Surface Treatment is a processing technology to improve the properties of metal surfaces. This improves rust prevention and corrosion resistance, and forms a basecoat for painting.

Nadcap Certificate for Surface Treatment (Chemical Processing)

Surface Treatment Lines

Surface Treatment at Tamagawa

Surface Treatment is one of the essential technology for aircraft products. Anodizing, Chemical Conversion Coating, Passivation, Plating and Black Oxide Coating are available at Tamagawa.

For Coating, qualified operators perform spray coating specialized in aerospace defense in the coating booth which meets the aerospace requirements for temperature and humidity control.

| Anodizing | Chemical Conversion Coating |

Passivation | Plating | Black Oxide Coating |

Coating | |

|---|---|---|---|---|---|---|

| Purpose | ・Corrosion resistance ・Increase hardness ・Paint adhesion |

・Corrosion resistance ・Paint adhesion |

Corrosion resistance | Corrosion resistance | Corrosion resistance | ー |

| Features | Dyeable | Low electrical Resistance |

Higher corrosion Resistance |

Uniform thickness plating (Electroless nickel plating) |

Higher peeling resistance |

Complied with Aerospace requirements |

|

|

|

|

|

|

|

| Material | Aluminum Alloy | Aluminum Alloy | Stainless Steel | ・Carbon / Alloy Steel ・Stainless Steel ・Copper Alloy ・Aluminum Alloy |

Carbon / Alloy Steel | ー |

| Method | Electrolyzation | Chemical reaction | Chemical reaction | ・Chemical reaction ・Electrolyzation |

Chemical reaction | ー |

| Specification | MIL-A-8625 | MIL-DTL-5541 MIL-C-5541 |

AMS2700 AMS-QQ-P-35 |

AMS2404 AMS2460 AMS2418 |

MIL-DTL-13924 | ー |

| Nadcap |  |

|

|

|

N/A | N/A |

FREE from Hexavalent Chromium

Tamagawa is the only Japanese company which has Hexavalent Chromium free (Type II) Nadcap accreditation.

Hexavalent Chromium is a conventional corrosion inhibitor but contains carcinogens. It is one of the RoHS-regulated substances and worldwide efforts to reduce the Hexavalent Chromium is in progress even in Aerospace industry.

*RoHS: Restriction of Hazardous Substances in Electrical and Electronic Equipment

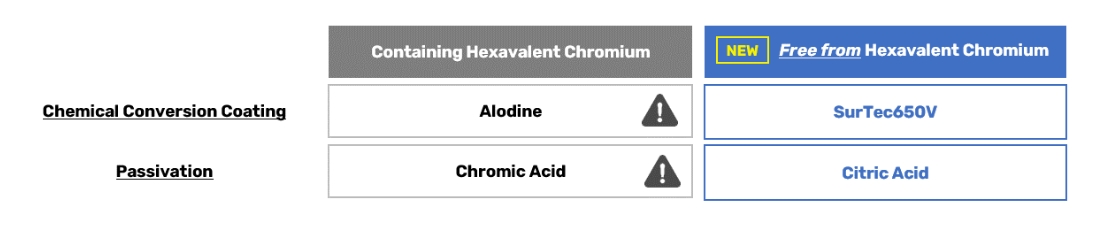

Recycle system of waste water

An ion-exchange waste water system enables to reuse 86% of the water used in Surface Treatment lines.

The buildings and equipment are designed to withstand a big earthquake. Water supply and drainage equipment can be automatically blocked in case of emergency of breakdown. This design and system prevent leaking the waste water from the outside of buildings / equipment.

Surface Treated Products

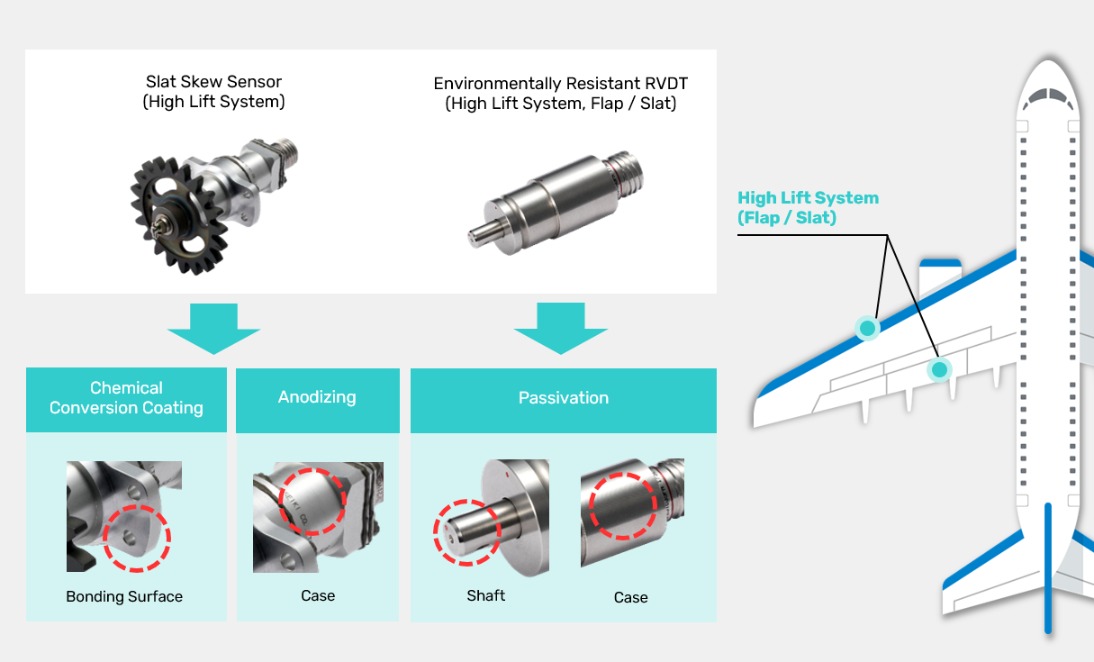

Tamagawa Levers, Motors and Sensors for High Lift System are surface treated by Chemical Conversion Coating, Passivation and Anodizing, etc. For example, Anodizing and Chemical Conversion Coating for Slat Skew Sensor and Passivation for Environmentally Resistant RVDT.

02. NonDestructive Testing

NonDestructive Testing

NonDestructive Testing is an inspection technology to detect minute surface flaws and internal defects without destroying the test piece.

This method is used not only for the inspection of Aerospace components, but also in a wide range of other fields such as medical and architecture.

Nadcap Certificate for NonDestructive Testing

NonDestructive Testing

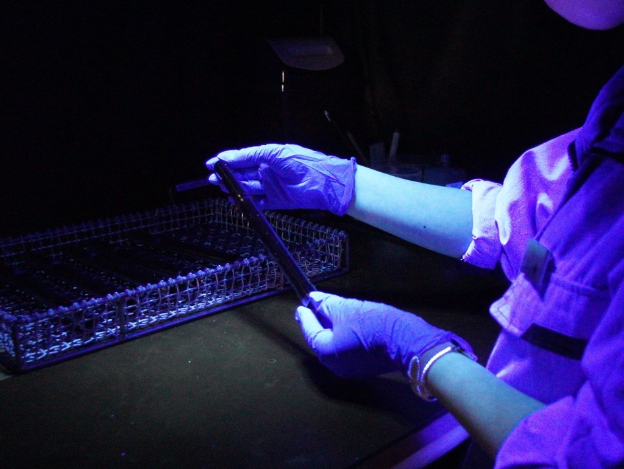

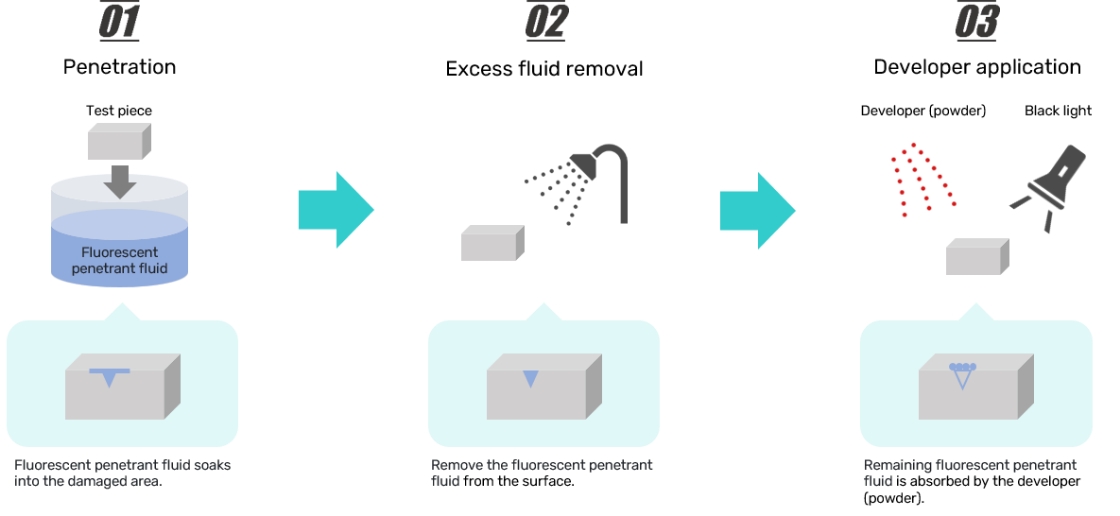

Fluorescent Penetrant Inspection (FPI)

Inspection to visually detect small open cracks on the surface of a test piece.

Principal

Apply the fluorescent penetrant fluid to the test piece.

Remove the excess fluid only from the surface, and then dry the test piece.

Apply the developer and shine black light on the area to be inspected.

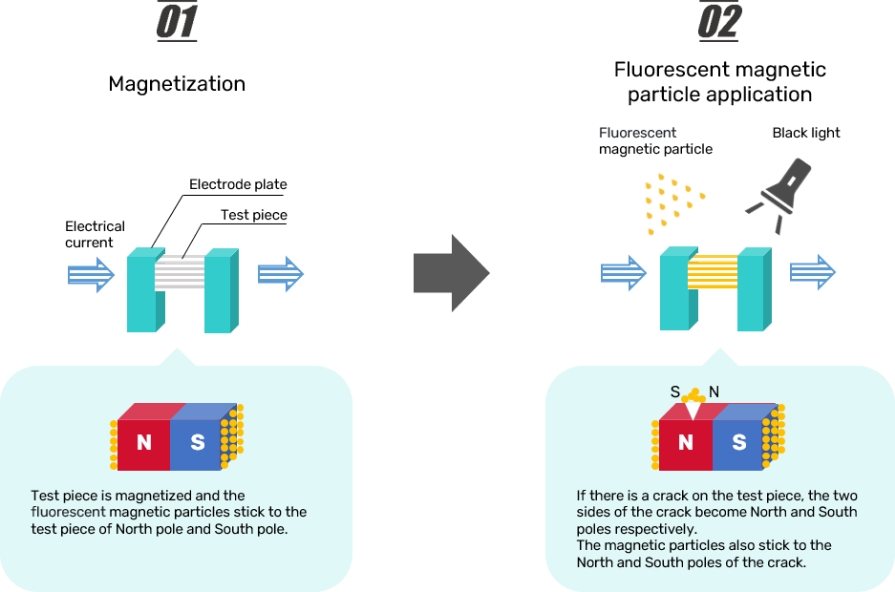

Magnetic Particle Inspection (MPI)

Inspection to apply an electrical current through the test piece and detect cracks on the surface using magnetism.

This inspection method is suitable to ferromagnetic materials such as steel and precipitation-hardened stainless steels like 17-4PH and 15-5PH.

Principal

Place the test piece between electrode plates, and apply an electrical current to generate a magnetic field on the test piece.

Apply fluorescent magnetic particle and shine black light on the area to be inspected.

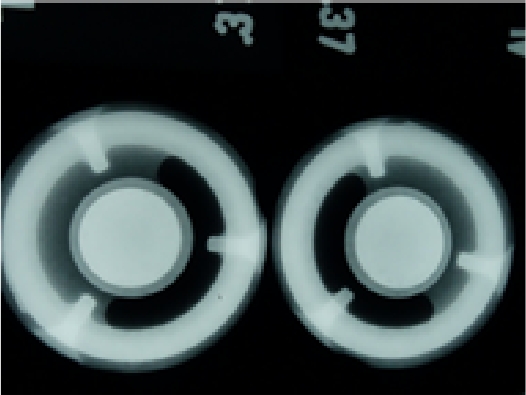

Radiographic Inspection

Internal condition of the test piece is inspected by X-Ray irradiation. In the aerospace industries, conventional inspection is X-ray film and digital X-ray is getting popular in recent years. Both digital and film inspection are available at Tamagawa.

Radiographic Inspection Equipment (Digital)

Developed photo (Film)

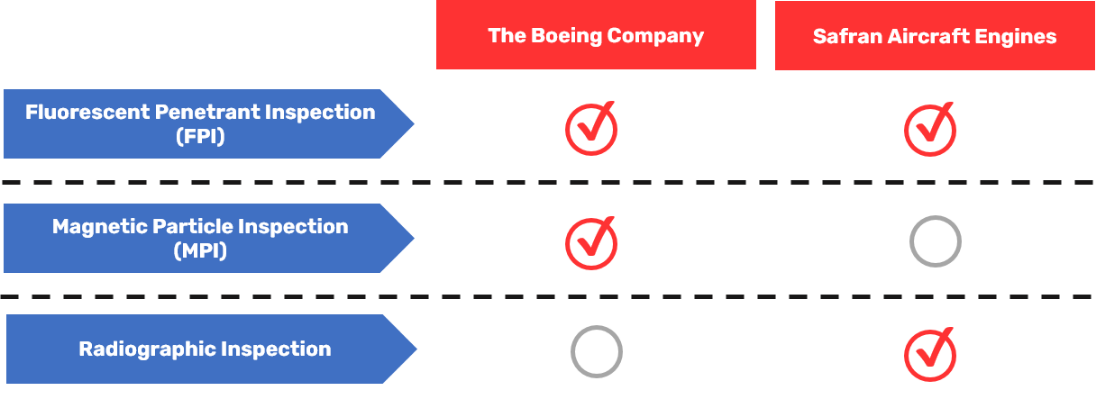

Tamagawa has achieved process certifications from our customers to meet customer’s demand.

For Fluorescent Penetrant Inspection and Magnetic Particle Inspection, NDT Level III technicians perform the tests with high skills and expertise.

NonDestructive Testing at Tamagawa

| Description | Materials | Applicable Specification |

|---|---|---|

| Fluorescent Penetrant Inspection (FPI) | All | ASTM E 1417 |

| BAC5423 (Boeing) | ||

| Pr-5000 (Safran) | ||

| Magnetic Particle Inspection (MPI) | Carbon / Alloy Steel Precipitation Hardening Stainless Steel |

ASTM E 1444 |

| BAC5424 (Boeing) | ||

| Radiographic Inspection | All | ASTM E 1742 |

| ASTM E 2033 | ||

| Pr-5200 (Safran) |

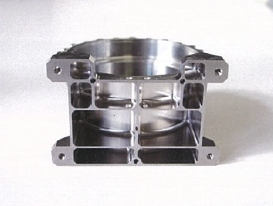

03. Machining

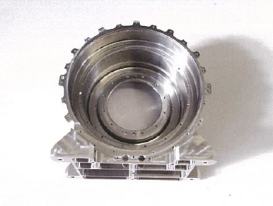

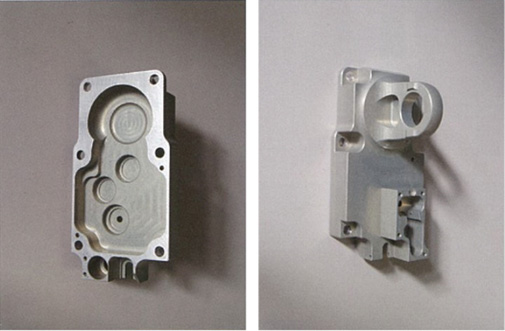

A wide variety of machine tools make available to machine aluminum, stainless steel alloys (austenitic, martensitic and ferritic), titanium alloys, chromium molybdenum steel and aluminum castings.

Space Components

Actuator for satellite

Size (mm): 130 x 140 x 90

Material: Ti-6L-4V

Processing equipment: Lathe /Wire cut / Machining center / Jig borer

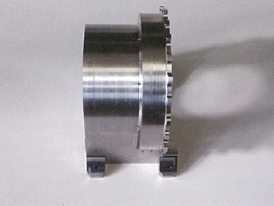

Aircraft Components

Aircraft actuator

Size (mm): 150 x 80 x 80

Material: A7075

Processing equipment: 5-axis machining center / surface treatment (anodized aluminum)

Impellers for fuel pump

Size (mm): Φ100 x 180

Material: A7075

Processing equipment: Lathe / 5-axis machining center

New Processing Equipment

Tamagawa has actively introduced some new processing equipment. For example, Five-axis machining center and Vertical machining center are a part of new equipment introduced in 2021.

Five-axis machining center

Vertical machining center

Don’t miss it!!

Introduction in next Newsletter

OUR TECHNOLOGIES

CAN HELP YOUR DEVELOPMENT

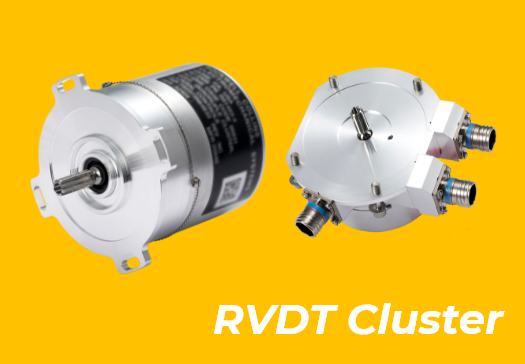

RVDT Cluster

TAMAGAWA RVDT Cluster with integrated gears is angular position sensor unit, equipped with maximum 5 RVDTs in the shell to realize redundancy.

Resolver with Gearbox

Gearbox for Resolver is available for reduction and acceleration. TAMAGAWA offers custom designed resolver with spur gear and planetary gear.