Motors for Carbon Neutral Flight in the FutureWhat Tamagawa can do Now for Environment

As one of the leading company of Motor’s R&D, Tamagawa has been working to develop motors contributing to Carbon Neutral Growth. With the rise of Electric aircraft and eVTOL, Tamagawa is exploring the motors which realize ”Less CO2 Emission”, “Fuel-saving”, “Electrification of Aircraft” and “Sustainability”.

01.Tamagawa Motors x Carbon Neutral Growth

With the growth of Carbon Neutral efforts in Aircraft industry, Tamagawa is actively involved in the Research and Development of Motors for Electric Aircraft, eVTOL and other contributive aircraft applications.

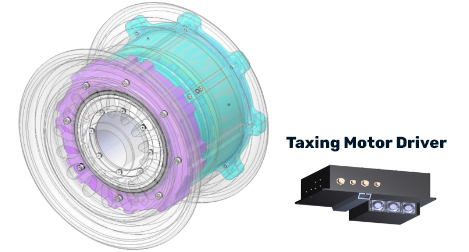

02.Electric Taxing Motor

CO2 Emission & Fuel-saving

Conventional way of taxing is fuel-consuming and releases large amount of carbon dioxide. Tamagawa developed Electric Taxing Motor which enables self-propelled taxing equipped in tires of Aircraft. This Motor contributes to reduce CO2 emission and fuel saving. This Motor is designed for Regional Jets having maximum speed with 20 knots.

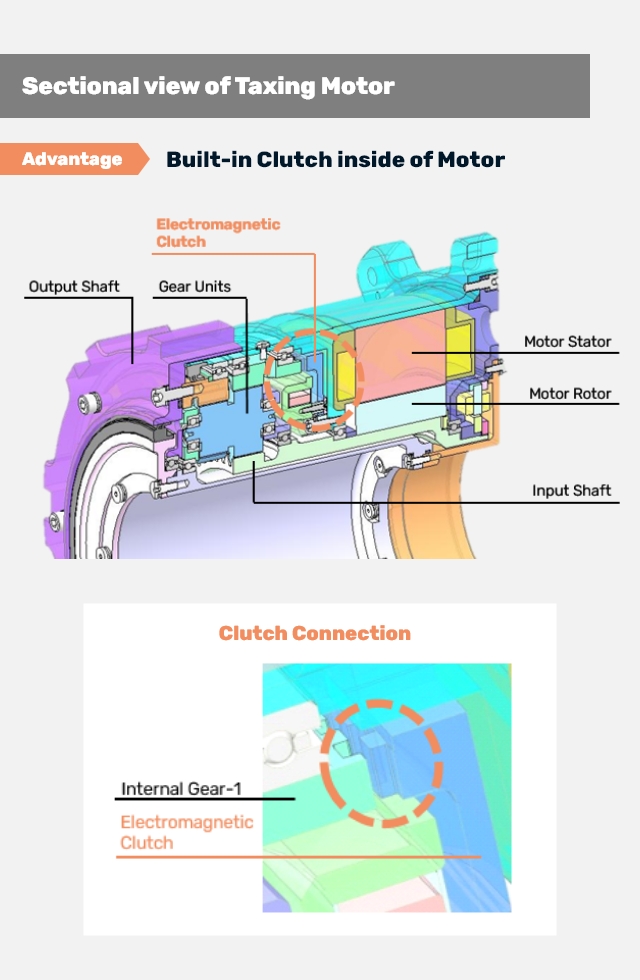

Taxing Motor

Taxing

Built-in clutch enables high output by combining gear units

Taking-off & Landing

Makes less susceptible to high-speed tire rotation by separating gear units

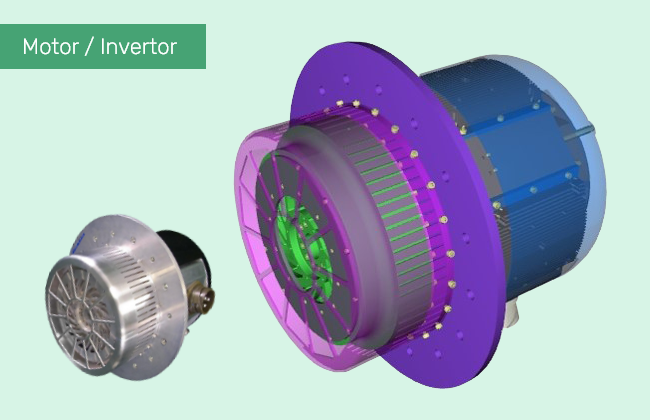

03.High Power Density Motor System

Contribution to Electrification of Aircraft

From 2020, Tamagawa has worked on research and development of High-power and High-density Motors / Inverters for hybrid electric and all electric aircraft. We are still making improvements for future Carbon Neutral Flight.

System Overview

Usage

- STEP 1

- Hydraulic Pump Application

Environmental Control System Fan Application - STEP 2

- eVTOL, Small aircraft

Description

Motor and Controller are integrated to reduce the weight of the entire system.

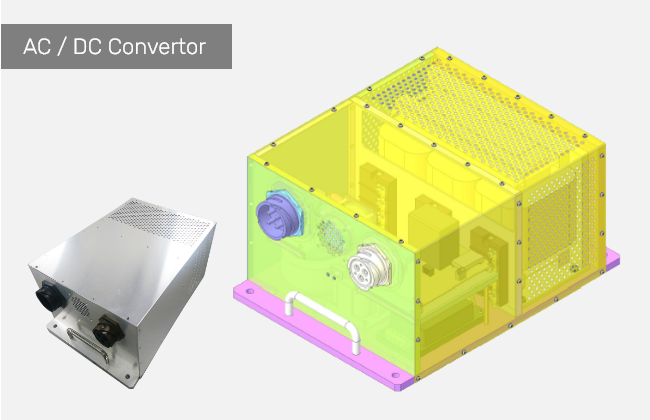

230 VAC input power is rectified by the Convertor and generates high voltage for motor system densification.

| Item | Specification |

|---|---|

| Motor Power | 20 kW |

| Rated Speed | 6,000 rpm |

| Motor Torque | 32 Nm |

| Power Weight Ratio | 4.0 kW/kg |

| Motor / Controller Efficiency | 95% |

| Cooling | Air Cooling |

| Input Power | AC230 Vrms, 3 phase, 400 Hz (NOM) |

| Temperature | -40 to 70 degree C |

| Altitude | 25,000 ft |

High Density

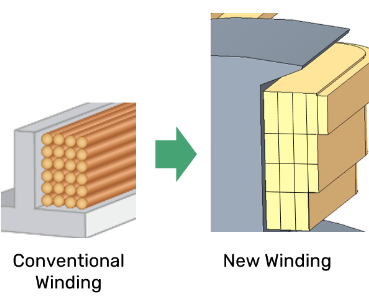

High density & weight saving winding with flat type aluminum wire

High Power

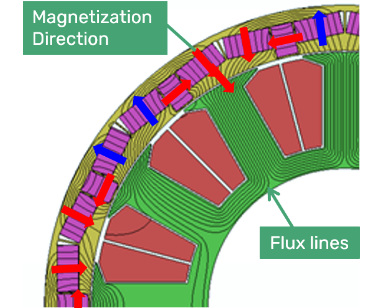

Special arrangement of magnet

(Halbach array)

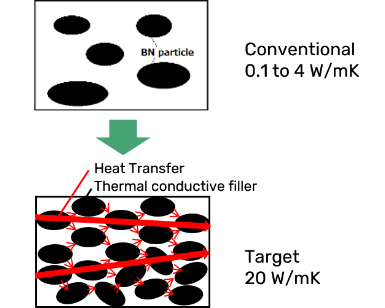

Advanced Cooling Technology

High thermal conductive material & Integrated fan with rotor

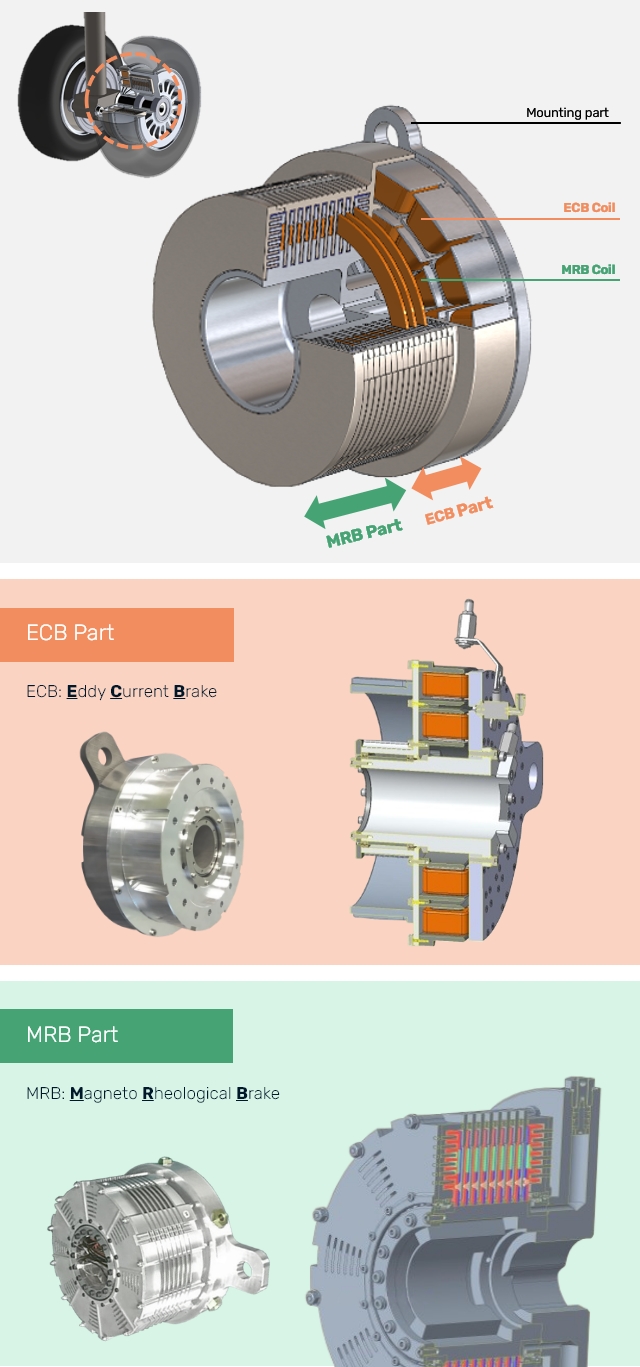

04.Hybrid Brake System

Low maintenance with sustainability

Current commercial aircrafts have contact friction brakes with multiple discs and this structure requires frequent inspections and overhauls due to disc wear. Tamagawa has developed contactless Hybrid Brake System using electro magnetic force which enables low maintenance with sustainability.

OUR TECHNOLOGIES

CAN HELP YOUR DEVELOPMENT

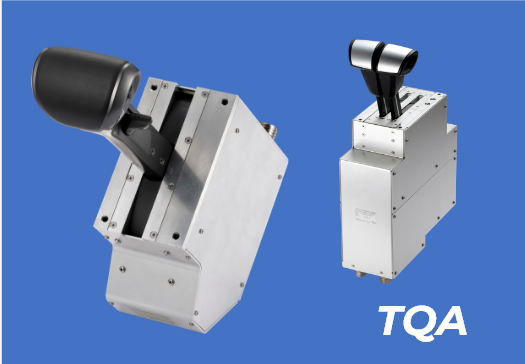

Throttle Quadrant Assembly

TAMAGAWA TQAs are used for commercial aircrafts, several RVDTs are installed for positioning & redundancy, output signals are provided to the FADEC.

Resolver with Gearbox

Gearbox for Resolver is available for reduction and acceleration. TAMAGAWA offers custom designed resolver with spur gear and planetary gear.