Deep Dive into Electro-Mechanical ActuatorGo behind the scenes of EMA Development / Manufacturing

Based on many years experience in development & manufacturing of Electro-Mechanical Actuator, Tamagawa Seiki Co., Ltd. is confident in the processes to achieve high performance & high quality. Let us show a part of our development & manufacturing processes of EMA.

01.Key to High Performance

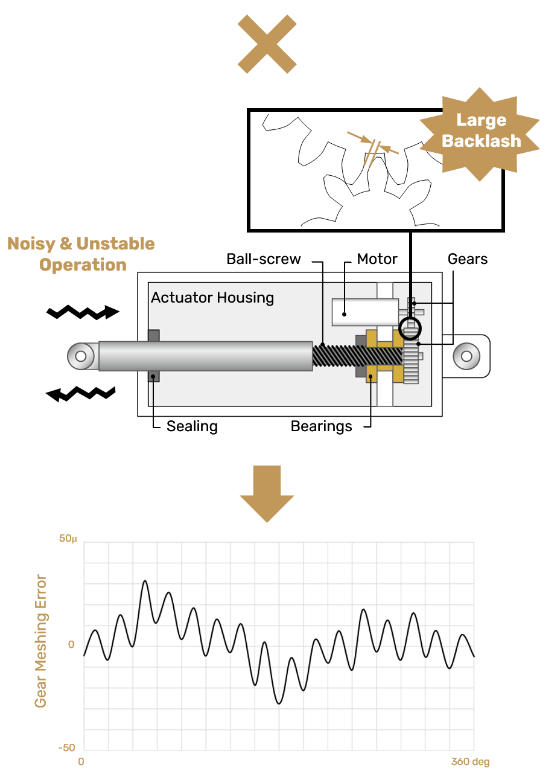

Reduction of Backlash

Minimizing the meshing error of the gears, speed fluctuations and operating noise can be reduced; Meanwhile, backlash can also be reduced. It means the machining of gears highly contributes to the performance of Actuators.

Tamagawa has abilities to design and manufacture gears in house and they have a key role in high performance Actuators.

・Unstable load output

・Operation with noise and vibration

・Less durability

・Stable load output

・Less noise and vibration

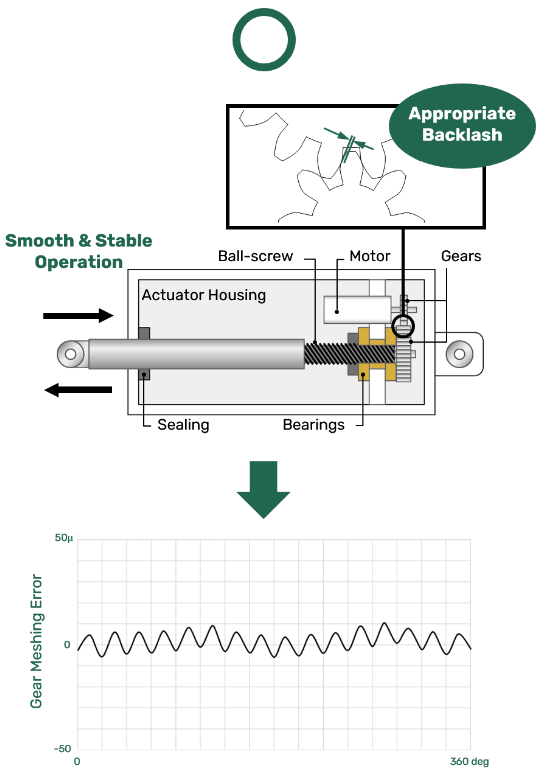

Suppression of Friction Torque

Improper fitting leads to increased friction torque and has a huge effect on the performance of Actuators. Additionally, this sets off vibration and noise, and makes an impact on the product life due to the seizure and damage of the ball bearings.

Tamagawa designs the whole structure considering the output load characteristics and load direction of Actuators so as to suppress the friction torque as much as possible.

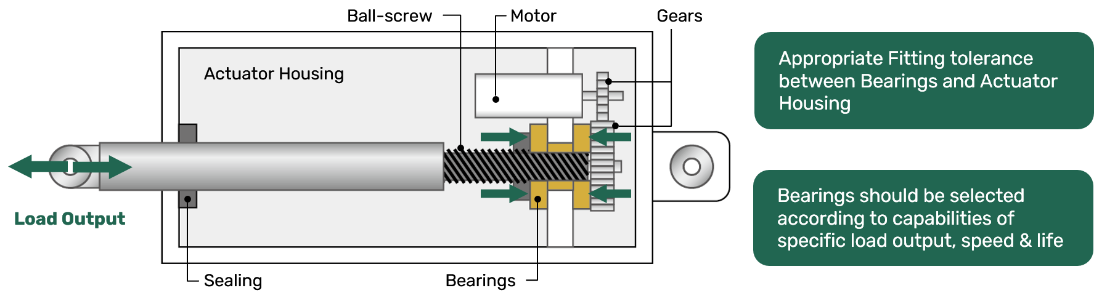

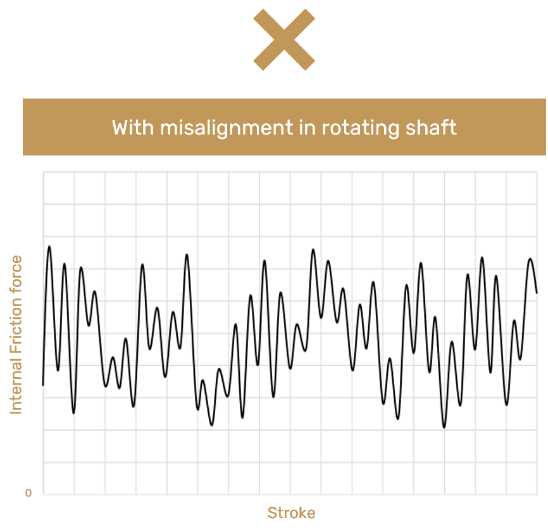

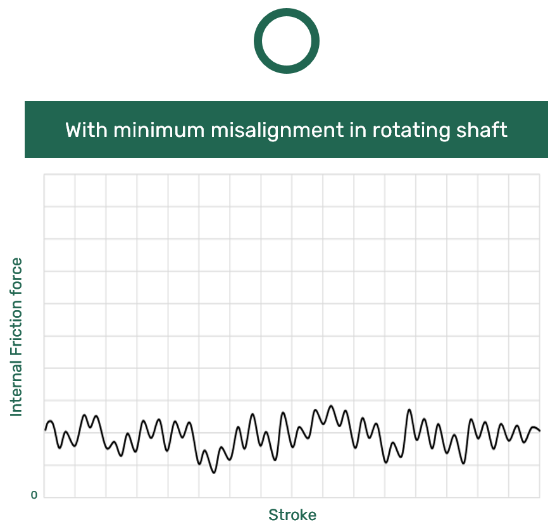

Mitigation of Misalignment

Misalignment of the rotating shaft causes noise, torque unevenness and rotational speed unevenness. In addition, the accuracy of output load is negatively affected, especially for the performance of the clutch and torque limiter.

Based on many years experience, Tamagawa focuses on the position accuracy of Actuator housing and select best fitted machining method.

・Insufficient and unstable load output

・Less durability of Bearings and Gears

・Bad effect on function of Clutch (output load limiter)

・Stable load output

・Clutch (output load limiter) works as expected

02.Environmental Resistance

According to DO-160G, Tamagawa Electro-Mechanical Actuators have been tested and demonstrated their reliability in required environmental conditions.

The key to the environmental resistance is their perfect sealing, material / device selection and lower resistance of bonding.

Waterproofness

These tests determine whether the equipment can withstand the effects of liquid water being sprayed or falling on the equipment or the effects of condensation.

(Reference: RTCA DO-160G, Section 10.0)

Sand and Dust

This test determines the resistance of the equipment to the effects of blowing sand and dust where carried by air movement at moderate speeds.

(Reference: RTCA DO-160G, Section 12.0)

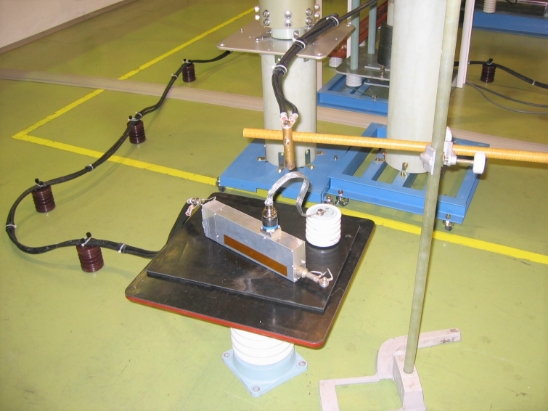

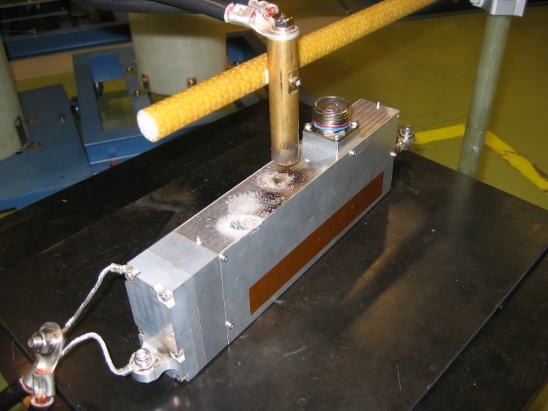

Lighting Direct Effects

The tests determine the ability of externally mounted equipment to withstand the direct effects of a lightning strike.

(Reference: RTCA DO-160G, Section 23.0)

03.Commitment to High Quality

Tamagawa has perfect confidence in quality of Electro-Mechanical Actuators. Our manufacturing processes include some special countermeasures to stabilize performance and eliminate failures of Actuators.

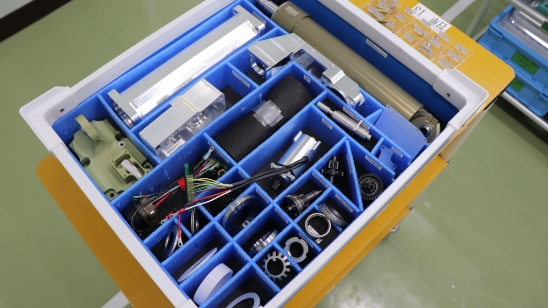

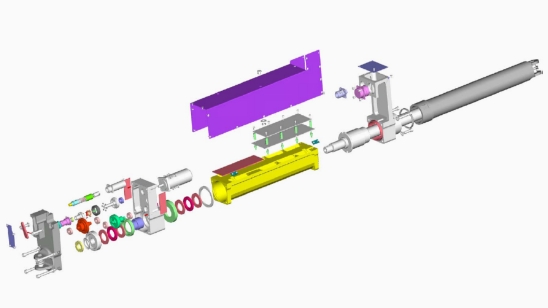

Sub Assembly

- Rear Housing Assy

- Gear Housing Front Assy

- Slide Head Assy

- Connector Assy

- Motor Assy

- Resistor Assy

- Free Fall Gear Assy

- Wire Assy

Final Assembly

Aging

“Aging” is a kind of running-in operation. Standalone piece parts and components of Actuator have consistent performance but assembled Actuator possibly have slight variation in its performance. Mechanical engagement, rotational sliding and linear actuation are a part of aging that stabilize the mechanical operation.

Freefall Test

The purpose of this test is to ensure the performance of Emergency Release Mechanism. Emergency release actuation force and stroke are inspected and recorded.

Screening

“Screening” is a process that eliminates initial failure of integrated electrical parts and interference of drive mechanism. In high / low temperature condition and vibration condition, this process detects failures and guarantees the operation of Actuator.

Sealing

Painting

Final Inspection

- Product Inspection (Dimensions etc.)

- Functional Inspection (Load test etc.)

- *Automatic Test Equipment

OUR TECHNOLOGIES

CAN HELP YOUR DEVELOPMENT

RVDT

Tamagawa RVDT provides linearly proportional voltages to the angular displacement with high reliability for vibration under extreme low/high temperature. Size 08, 10 and 11 are available in Tamagawa's RVDT series.

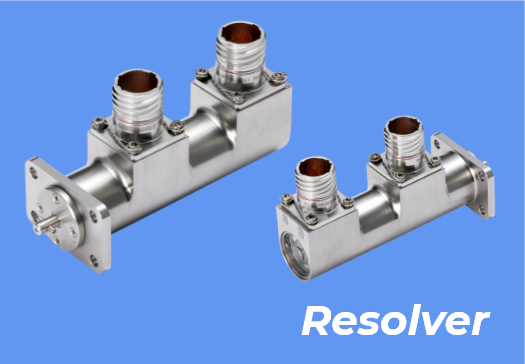

Resolver

Gearbox for Resolver is available for reduction and acceleration. TAMAGAWA offers custom designed resolver with spur gear and planetary gear.